MELD Technology wins in SAE Create the Future Design Contest

October 19, 2018

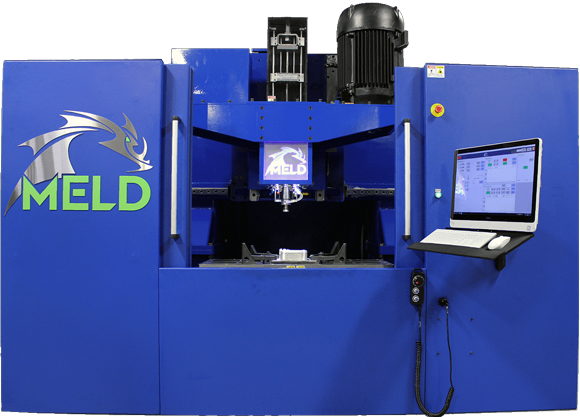

Meld Manufacturing Corporation’s B8 Model MELD machine (Courtesy MELD Manufacturing Corporation)

MELD™ Manufacturing Corporation, Christiansburg, Virginia, USA, has been announced as the winner in the Robotics/Automation/Manufacturing category of the Society of Automotive Engineers’ (SAE) Create the Future Design Contest for its patented MELD technology. The contest, organised by SAE’s Tech Briefs Media Group, recognises engineering across seven categories. The 2018 edition of the contest saw more than eight-hundred entries from over sixty countries.

MELD technology is a no-melt welding process that can be used for metal Additive Manufacturing, coating, repairing and joining. The process allows users to work with previously unweldable materials and avoid issues surrounding melt-based technologies.

MELD is also highly-scalable, using equipment which can be increased in size to produce the largest parts possible. In addition, it can be installed on robotic arms, enabling the possibility of onsite repairs in areas where current technology cannot reach, such as battlefields and shipyards.

This is the third industry recognition for MELD since its official launch early in 2018. In April 2018, the company received the Innovation Award at Rapid + TCT in Fort Worth, Texas, USA, and in August 2018, MELD was named as a finalist in the R&D 100 Awards, the winners of which will be announced in November 2018.

Nanci Hardwick, MELD Manufacturing CEO, commented, “MELD is revolutionary. It represents an opportunity for engineers, designers and manufacturers to ‘Create the Future’ of materials, product design and fabrication processes. We’re grateful for the recognition that SAE and the judges have given MELD.” The MELD team will officially accept their win at an awards dinner on November 9, 2018, at the Water Club in New York.