MELD receives RAPID + TCT Innovation Award

April 26, 2018

MELD Manufacturing Corporation has been selected from the more than 300 exhibitors at RAPID + TCT 2018 as the recipient of the show’s Innovation Award. The Innovation Award is said to recognises the most groundbreaking new product or service with industry-changing potential.

MELD Manufacturing Corporation, which was launched earlier this month as a subsidiary of Aeroprobe Corporation, was selected for the award for their patented MELD technology.

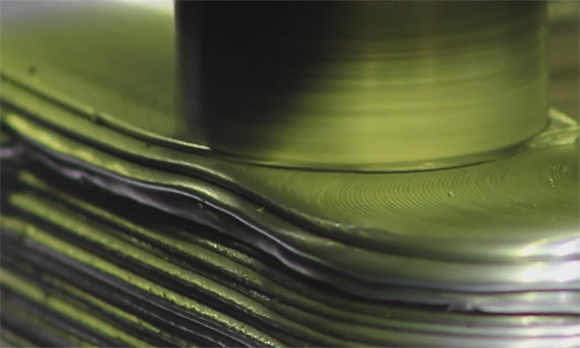

MELD is a unique process for Additive Manufacturing that avoids melting the metal, thereby eliminating issues associated with melt-based processes. MELD’s open-atmosphere operation and scalable equipment is also said to make it more efficient and capable of making larger parts than similar processes. In addition to Additive Manufacturing, MELD can be used to repair, coat, and join a wide range of materials, including some metals that cannot be welded with traditional processes.

“The MELD technology is a revolution,” stated MELD Manufacturing Corporation CEO Nanci Hardwick. “To be recognised at RAPID by these industry leaders demonstrates just how much potential MELD has to change the way we think about manufacturing. We want to see MELD adopted across industries, so it’s exciting to see genuine interest from such a diverse crowd.”

The winner of the Innovation Award is selected by a panel of industry experts. This year’s group included judges from industry, government, and academia.

“To earn this award our first year at RAPID is an honor,” added MELD Additive Manufacturing Manager Chase Cox. “MELD is on its way to innovating a number of industries and this award is a great milestone.”