Medtronic launches platform for Additive Manufacturing of complex titanium spinal implants

May 9, 2018

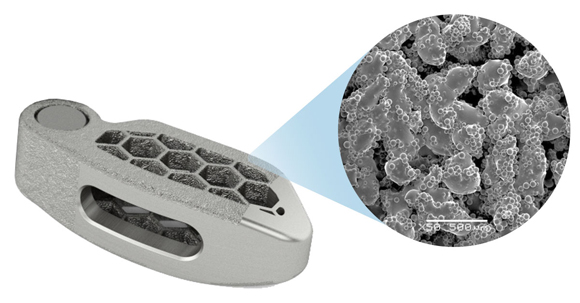

The ARTiC-L Spinal System incorporates a honeycomb structure to encourage osseointegration of the surrounding bone (Courtesy Medtronic plc)

Medtronic plc, Dublin, Ireland, today has launched a titanium Additive Manufacturing platform which it states enables more complex designs and integrated surface technologies for spinal surgical implants. The announcement was made during the American Association of Neurological Surgeons (AANS) annual meeting in New Orleans, Louisiana, USA.

The new platform, titled TiONICTM Technology, is an Additive Manufacturing technique said to create enhanced surface textures using a differentiated laser method. This enables the production of implants with rough three-dimensional surface structures which imitate natural trabecular bone morphology, increasing osteoconductivity and promote bone in-growth (osseointegration).

The first implant to be manufactured using the TiONIC process is its ARTiC-LTM spinal system, which incorporates a ‘honeycomb’ structure. The titanium implant is designed for use in transforaminal lumbar interbody fusion spinal surgery. As well as encouraging osseointegration of the surrounding bone, the honeycomb structure reportedly provides improved mechanical load distribution across the implant.

“ARTiC-L is an important component of Medtronic’s portfolio of reproducible solutions for minimally invasive procedures,” stated Doug King, Senior Vice President and President of Medtronic’s Spine Division, which is part of the Restorative Therapies Group at Medtronic. “Our 3D printed TiONIC Technology allows devices such as ARTiC-L – and our future interbody implant portfolio – to offer surgical advantages not traditionally possible.”

Dr Colin C Buchanan, a neurosurgeon at the Colorado Brain and Spine Institute, USA, commented, “Surface advancements, like TiONIC Technology, have emerged as a paradigm shift in interbody fusion implants. Implants utilising newer surface technology can help stimulate a cellular response and give me greater confidence that the patient will have a successful fusion.”