Markforged to acquire Digital Metal

July 12, 2022

Markforged, Watertown, Massachusetts, USA, has announced that it has entered into a definitive agreement with Höganäs AB, Sweden, to acquire Digital Metal, extending Markforged’s capabilities into high-throughput production of metal additively manufactured parts.

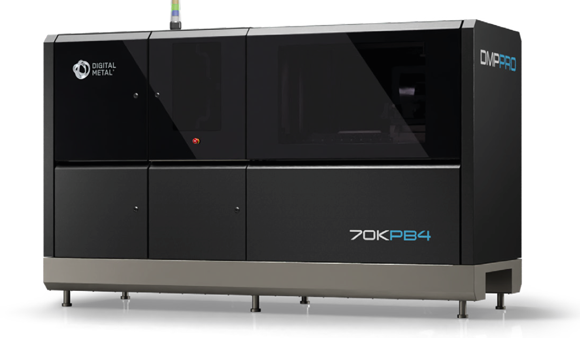

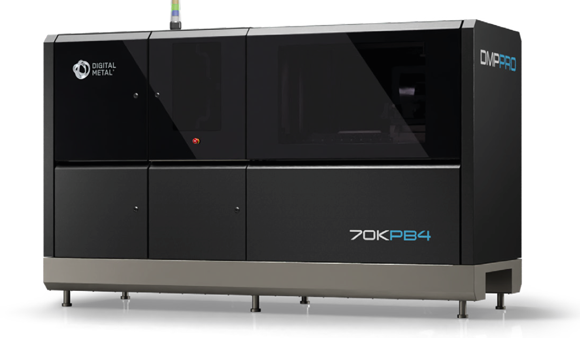

Markforged sees Binder Jetting (BJT) as a highly scalable Additive Manufacturing technology for production-grade parts using a variety of metal materials. Digital Metal’s solution is designed to provide high-precision, best-in-class part quality and reliability. Powder Binder Jetting complements the existing Digital Forge offering, and will expand Markforged’s addressable market by solving new customer problems.

“With the Digital Metal acquisition, Markforged is advancing our vision for distributed manufacturing by enabling the reliable, high volume production of precise metal parts at the point of need. Infusing Digital Metal’s solution into The Digital Forge platform allows us to address new applications in the medical, automotive, luxury goods and other industries,” stated Shai Terem, president and CEO of Markforged. “The Digital Metal team has created a robust and scalable solution that complements our existing technologies. I look forward to welcoming their talented people to Markforged.”

Founded in 2003, Digital Metal is a wholly-owned subsidiary of Höganäs AB and the creator of a proprietary Binder Jetting AM technology. Known for high productivity, excellent surface quality and superior resolution, Digital Metal printers have been used to produce hundreds of thousands of parts, including parts for leaders in consumer products, academia, and the automotive industry. Markforged sees significant opportunities to further accelerate Digital Metal adoption through integrated software capabilities and a global go-to-market engine.

“Markforged’s easy-to-use platform, best-in-class software capabilities and material expertise felt like a natural fit for the future of our technology,” said Christian Lönne, CEO of Digital Metal. “With Markforged’s experience and go-to-market scale, we are confident that we will be able to grow our technology together and help more manufacturers produce the high-volume metal parts they need to drive highly productive and cost efficient operations.”

As part of the transaction, Markforged has agreed to pay Höganäs approximately $32 million in cash, approximately 4.1 million shares of Markforged common stock and approximately $1.5 million in cash to settle certain intercompany balances, subject to certain adjustments. The acquisition of Digital Metal is expected to close during the third quarter of 2022, subject to customary conditions.