Markforged launches Blacksmith AI software to enable smart factories

May 24, 2019

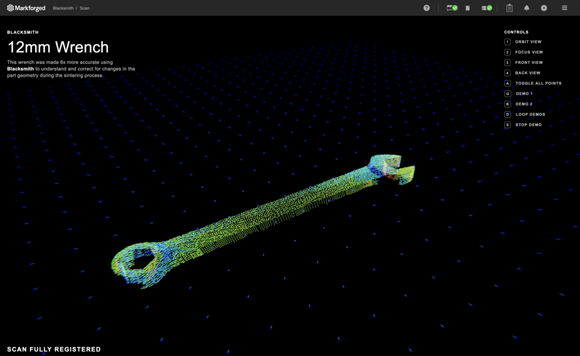

Markforged’s new Blacksmith AI software automatically adjusts programming to ensure every part is produced as designed (Courtesy Markforged)

Markforged, a supplier of metal and carbon fiber Additive Manufacturing systems, headquartered in Watertown, Massachusetts, USA, has introduced Blacksmith, which the company states is the first Artificial Intelligence (AI) powered software that makes manufacturing systems ‘aware’, enabling them to automatically adjust programming to ensure every part is produced as designed.

Blacksmith is reported to be a breakthrough in smart factories. “For the last hundred years, machines have been unaware of what they’re creating and would happily waste millions of dollars producing out-of-spec parts. We’re going to fix that by connecting the machines that make parts, and the ones that inspect them, with a powerful AI,” stated Greg Mark, CEO of Markforged. “Much like the way Tesla is building autopilot for cars, we are building an autopilot for manufacturing.”

Markforged states that starting with its Metal X and X7 AM systems, Blacksmith will create a continuous feedback loop to make additively manufactured parts more accurate. Blacksmith reportedly analyses a design, compares it to the scanned part, and automatically adapts the end-to-end process to produce in-spec parts. The company explains that the intelligent software also cuts waste and accelerates time to market and will be particularly powerful for the new generation of metal Additive Manufacturing. Markforged reports that the latest breakthrough methods require sintering – a process, according to the company, that notoriously distorts parts. Blacksmith is expected to eliminate this challenge and deliver precise parts post-sintering.

Mark added, “3D printing is just the start – we plan to extend the Blacksmith AI to connect all machines in your factory. We will enable the first generation of machines that know what they’re supposed to make, and can adjust themselves to produce the right part, every time.”

Blacksmith is expected to be available later this year.