Markforged announces Digital Source on-demand parts platform

September 19, 2023

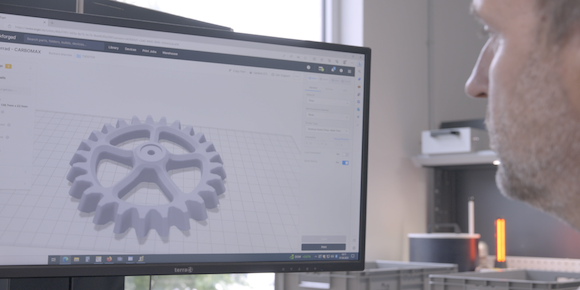

Markforged, based in Watertown, Massachusetts, USA, has announced the release of Digital Source, an on-demand parts platform designed to facilitate the licensing of Additive Manufacturing for manufacturer-certified parts. This allows for the production of parts when and where they are needed, eliminating the need for physical inventory management and the associated costs and complications.

Digital Source enables vendors to securely upload digital part designs, which can then be licensed to customers, distributors, and contract manufacturers. Once uploaded, end-users of Digital Source will have the option to license the rights to build parts either onsite or through an expanding network of approved build service providers.

“Digital Source gives us the agility to print spare parts where they are needed, so we can get machinery back up and running much faster and minimise our downtime,” stated Jeremy Haight, Principal Engineer at Vestas Wind Systems A/S, a global leader in sustainable energy solutions. “Time equals a very high dollar value for us — a line down in one of our factories is a big deal, but a turbine that has gone down can cost even more. If we can access and print the part we need, we can get that line or turbine back up and operational much quicker.”

Shai Terem, CEO of Markforged, added, “Digital Source unlocks a new way of managing supply chains. Every day a manufacturing line is down due to broken or worn parts can cost millions of dollars in lost productivity. Availability of spare parts is critical to manufacturers’ success — but keeping an extensive physical inventory ties up capital in parts that may go untouched for years. Digital Source not only can simplify logistics, but can also build resiliency into the supply chain and increase profitability as a result of these efficiencies. With Digital Source, parts can be digitised and printed at the time and point of need without the need to be manufactured in advance, shipped and stored until needed.”

Digital Source is designed to provide consistent and reliable turnkey production for Additive Manufacturing parts. Markforged integrates Additive Manufacturing software, materials, and hardware with end-to-end process control in an effort to deliver on the promise of digital warehousing. Vendors have the ability to specify and lock manufacturing process requirements, ensuring that customers receive manufacturer-certified parts whenever needed. To protect designs, robust security measures safeguard digital part files, and encrypted build instructions are sent directly to manufacturers, allowing customers to simply ‘Press Print.’

BMF GmbH, a vendor on Digital Source based in Chemnitz, Germany, is a highly specialised manufacturer of complex sand blasting machines. They have over 200 installations worldwide, each featuring sixty additively manufactured components. Typically, these components are replaced every three to four months when the machines are running at full capacity.

“We needed a significant amount of storage capacity to be able to stock all the spare parts, and often, the extended delivery time is linked to the customer’s ordering process, as the administrative procedures frequently take too long, when BMF ships the spare parts on the same day,” Ronny Bernstein, CEO of BMF GmbH, commented. “Via Digital Source, the component can be printed on-site the moment a failure or wear is detected.”

Both vendors and customers of Digital Source are said to be able to benefit from reduced inventory costs and simplified replacement part operations. This can lead to increased productivity, profitability, and customer satisfaction. Customers and service centres have the ability to build design revisions directly from Digital Source, eliminating waste from disposing of outdated parts and reducing the risk of installing the wrong part version.

“Above all is uptime for our customers. The machine must run and the customer must be able to continue producing. Now the majority of advanced composite parts are printed directly at the customer location, which not only brings down the time it takes to receive the part, but also brings shipping costs and CO2 emissions down, which is on all companies’ minds more than ever before,” added Bernstein.

Project DIAMOnD is an emergency response network for on-demand Additive Manufacturing. It involves small and medium-sized manufacturers operating 300 Markforged machines. Facilitated by Automation Alley, a Michigan initiative in Oakland County, Project DIAMOnD plans to implement Digital Source into the network. This implementation aims to enhance the adoption of Additive Manufacturing on the factory floor.

“We value Markforged because of its strong emphasis on protecting the digital recipe of parts and enforcing the standards of quality for remotely-printed parts,” explained Pavan Muzumdar, Chief Operating Officer of Automation Alley and CEO of Project DIAMOnD. “We believe the future of manufacturing is distributed manufacturing. By connecting our physical world through secure digital inventories, Digital Source is very strongly aligned with our vision for the future.”

Download Metal AM magazine