MachineWorks releases Polygonica 3.1

November 19, 2021

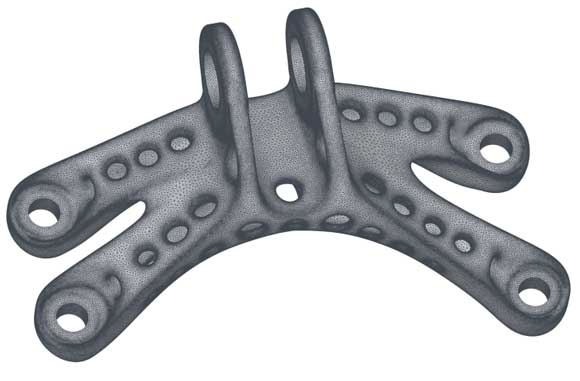

MachineWorks Ltd, based in Sheffield, UK, has announced the release of Polygonica 3.1 SDK for polygon mesh modelling. Polygonica software is intended to help companies, in a range of industrial markets, solve complex 2D and 3D geometrical problems. Main functions include healing, Booleans, offsetting, mesh analysis, remeshing, simplification, data reduction, defeaturing and point-cloud manipulation and meshing.

“In Polygonica 3.0 we added significant new areas of functionality,” stated Dr Fenqiang Lin, Managing Director of MachineWorks. “The 3.1 release cycle has seen great efforts to further improve existing functionality in response to customer feedback, and also development of interesting new techniques we believe have lots of potential.”

Key improvements in Polygonica 3.1 include:

- New .NET wrappers supporting programming with C# and other .NET languages

- Multithreaded Boolean union of multiple solids, including out-of-core support

- Identification of curves along curvature extrema of a mesh (crests and troughs)

- New non-manifold geometry healing that works on open surfaces with defects

- Recognition of screw threads in surface detection

- Memory-efficient method for slicing huge numbers of solids

- Optimisation of mesh export to support faster updates to external graphics

- Direct export of mesh solids that conform to Siemens Parasolid

- Remeshing

- Shrink-wrapping

- Selection

- 2D Profile operations

- 3D curve operations

“We’ve seen a significant increase in adoption of remeshing during the last year, partly driven by the addition of curvature sensitive remeshing in Polygonica 3.0,” continued Dr Lin continued. “We are proud that Polygonica’s best-in-class mesh healing now combines with Polygonica’s high quality, multithreaded remeshing to provide a powerful mesh preparation tool for the CAE simulation and analysis market.”

Richard Baxter, Head of Sales and Marketing, added, “Although we’re now seeing significantly increased demand for Linux, the addition of .NET wrappers will please a lot of users building more traditional desktop solutions. Polygonica marches on.”