Link3D launches Post-Production Management app to streamline AM workflow

October 14, 2020

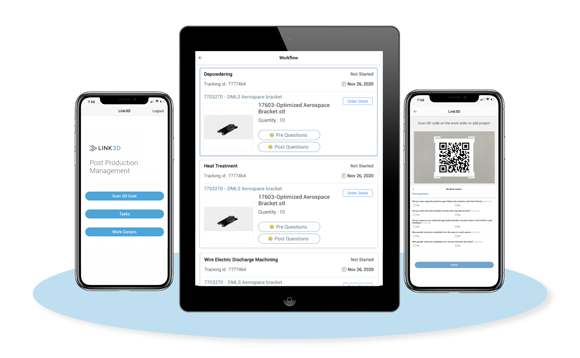

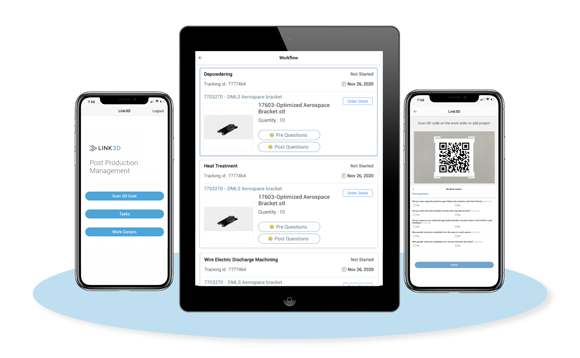

Link3D, Boulder, Colorado, USA, has launched its first mobile app: Post-Production Management. The company states that the new application will change the way companies and organisations manage their post-production processes and provide a streamlined workflow by allowing quick and efficient management of additively manufactured parts and creating a digital thread.

The company offers solutions for organisations to scale their Additive Manufacturing processes and enables workflow automation by connecting IT, hardware, and software technologies with APIs. With the ability to configure order forms and collect data in any language, facilities can accept, quote, and cost orders from anywhere in the world.

The Post-Production Management app is said to allow teams to maximise and optimise end-to-end processes in conjunction with the Production Dashboard that automatically keeps track of queued, completed and failed parts.

Link3D’s app will enable its customers to:

- Locate parts by (1) scanning a QR code (2) filtering by tasks (3) Work Center hub

- Review and update the status at each step from ‘Not Started’ to ‘Arrived,’ ‘In Progress,’ ‘Completed,’ or ‘Failed’

- Automatically route the parts through a series of Work Centers defined by the traveller

- Manage yield by tracking how many parts were completed successfully at each Work Center, and how many require rebuilding

- Track failure reasons for each Work Center to increase traceability of yield management on the production floor

- Track the labour and machine hours required to complete each post process for different parts and Work Orders

- Complete pre- and post-checklists to ensure that the technician successfully followed all work instructions

- Upload and view documentation/images for traceability of happenings at each Work Center

- View additional order details to provide context for the full order including customer information and detailed production requirements for a given part

According to Link3D, as more companies begin to adopt AM processes, it will be critical that each job is as seamless and connected as possible. The company states that its new Post-Production Management app gives companies control of their jobs and complete transparency of each step in the production process

Lara Janse van Vuuren, Technical Program Manager at Link3D, commented, “We have seen the Post Production app streamline the post-processing steps and increase the traceability without adding overhead to every task. The paper trail is eliminated without losing the sign-offs and accountability for each step after the printing process.”