LimitState:FORM optimisation software promises to reduce weight and material consumption

July 12, 2016

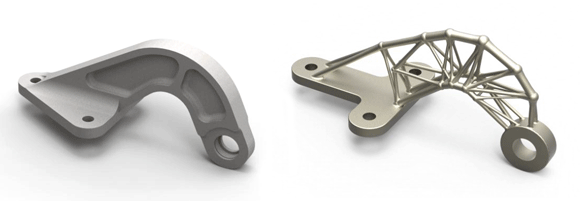

An automotive bracket prior to optimisation (left) and after optimisation (right)

LimitState has launched a new software package which, the company states, promises to revolutionise the work of design engineers needing to reduce the weight and material consumption of components. LimitState:FORM enables design engineers to generate high fidelity optimised forms directly, accelerating their optimisation workflow. It is claimed this will unlock the potential of Additive Manufacturing for many, while also representing a step forward for designers using traditional manufacturing methods.

LimitState:FORM is a conceptual design tool which identifies entirely new component designs that are often much lighter and more efficient than traditional forms. It is unique in performing layout and geometry optimisation in combination, while also enabling users to directly manipulate the solution obtained.

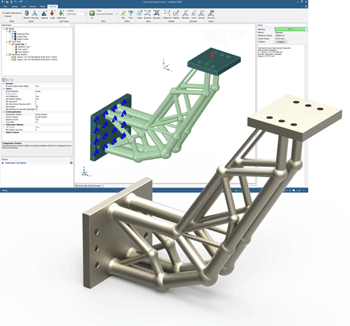

Rather than generating a ‘mesh’ as traditional tools do, the software creates an optimised parametric geometry form that can be inspected and edited directly. This is claimed to be straightforward as the software incorporates powerful direct modelling technology from ANSYS SpaceClaim. The optimisation technology used means that LimitState:FORM tends to get closer to the mathematical optimum than other methods. It is also unique in reporting just how close a solution is to the likely mathematical optimum, taking a great deal of guesswork out of the optimisation process.

LimitState has worked closely with a number of industry partners to develop the software, optimising parts used in aero engines, automotive components and satellite construction. The software is already in use at The Mercury Centre, an advanced manufacturing research centre located in Sheffield, UK, where it has reportedly produced significantly more efficient component forms than have been possible using other tools.

LimitState has worked closely with a number of industry partners to develop the software, optimising parts used in aero engines, automotive components and satellite construction. The software is already in use at The Mercury Centre, an advanced manufacturing research centre located in Sheffield, UK, where it has reportedly produced significantly more efficient component forms than have been possible using other tools.

“LimitState:FORM is the only tool to include both layout optimisation and geometry optimisation, generating a model that can be worked on immediately with standard CAD tools,” stated LimitState Managing Director Matthew Gilbert. “Optimisation is a crucial technique in next generation engineering design, targeting production methods such as additive manufacturing. Making optimisation tools which are both more effective and easier to use represents a milestone for the industry.”

“Optimisation is becoming a crucial addition to every design engineer’s armoury, and we’re delighted that our technology is helping to make this tool easy to use,” stated Peter Kelly, Sales Director, Northern Europe at ANSYS SpaceClaim. “The inclusion of ANSYS SpaceClaim’s powerful geometry capabilities in LimitState:FORM means engineers can optimise their model and design and edit it in one fluid workflow. This is a breakthrough for any design engineer who wants to reduce the weight and cost of components and structures.”