LIFT adopts Exum’s new Massbox for rapid chemical characterisation

March 28, 2023

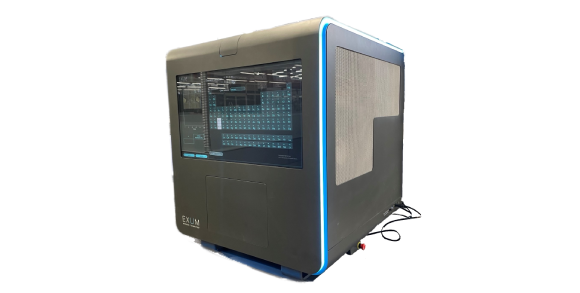

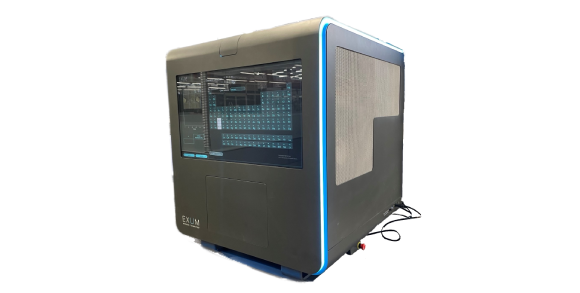

LIFT, a US Department of Defense (DoD) national manufacturing innovation institute based in Detroit, Michigan, has announced that it has taken delivery of a Massbox from Exum Instruments, Denver, Colorado. The Massbox, a mass spectrometer designed for easy use on solid materials, will be situated in LIFT’s metrology laboratory within its advanced manufacturing facility.

The Massbox is reputedly the industry’s first Laser Ablation Laser Ionisation Time-of-Flight Mass Spectrometer capable of trace level detection for the entire periodic table. To strengthen LIFT’s work in designing, building and testing new materials for future components for the DoD and industry, the Massbox determines the chemical composition of any solid material, from a pressed powder to a solid part. Previously, such testing could be cumbersome, inefficient, with limited scope of elemental results, and generally requiring subcontracting with testing houses. The Massbox provides quantitative chemical analysis of metallic, trace, and low-mass (e.g., carbon, oxygen) elements in a single analytical session.

A desktop platform, the Massbox combines Exum’s patented laser-ablation ionisation (LALI) source with industry-leading time-of flight (TOF) mass analyser. LALI utilises one laser to remove material from a solid sample and a second laser to subsequently ionise neutrals. This process removes many of the elemental fractionation, spectral interferences, and matrix effects that plague other techniques. Its interface is said to be intuitive and allows a user without chemistry expertise to obtain impactful results with just a few hours of training.

“The Massbox brings mass spectrometry out of the traditional laboratory environment, combining high performance with intuitive operations in a compact package,” stated Jeff Williams, CEO/CTO and co-founder of Exum Instruments. “Addressing the challenges associated with conventional instruments, this versatile technology is an ideal tool for quality control, failure analysis, material development, and more.”

Noel Mack, Chief Technology Officer, LIFT, concluded, “As LIFT continues its focus on the intersection of materials, processing and systems engineering, this new tool is a game changer for LIFT and our broader ecosystem. It is sure to serve as a vitally important resource in advancing high-tech research and development in Detroit and beyond.”

Download Metal AM magazine