Liebherr begins serial metal Additive Manufacturing of aerospace components

February 11, 2019

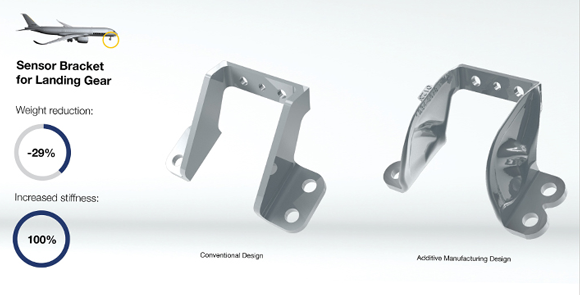

Additively manufactured nose landing gear bracket produced by Liebherr-Aerospace for the Airbus A350 XWB (Courtesy Liebherr-Aerospace & Transportation SAS)

Following approval by Airbus, Liebherr-Aerospace & Transportation SAS, headquartered in Lindenberg, Germany, has begun the serial metal Additive Manufacturing of components for the company, beginning with nose landing gear brackets for the Airbus A350 XWB. These brackets will be the first Airbus parts to be qualified for Additive Manufacturing in titanium.

Josef Gropper, Managing Director and COO of Liebherr-Aerospace & Transportation SAS, stated, “This milestone shows that we are a recognised pioneer and trusted partner in the aerospace world. We are planning to produce more complex components in the future in order to fully utilise the potential of Additive Manufacturing.”

Liebherr launched its Additive Manufacturing / Research & Technology project, headed by Alexander Altmann, more than six years ago from its Lindenberg facility. On March 30, 2017, Airbus successfully flew Liebherr-Aerospace’s additively manufactured spoiler actuator valve block on a flight test A380. This marked the first additively manufactured primary flight control hydraulic component flown on an Airbus aircraft.

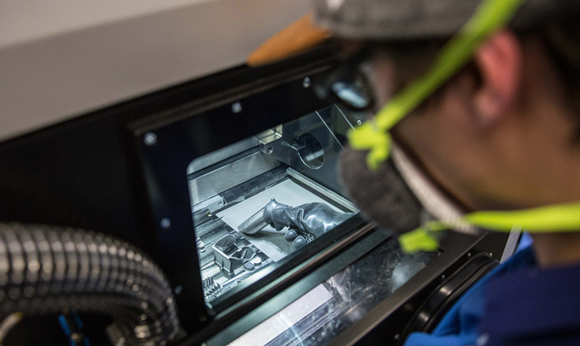

Powder removal from the build chamber at Liebherr-Aerospace’s metal Additive Manufacturing facilities (Courtesy Liebherr-Aerospace & Transportation SAS)

In Autumn 2017, Liebherr-Aerospace Lindenberg GmbH, Liebherr’s centre of excellence for flight control systems, landing gears, gears and gearboxes, achieved authorisation by the German Federal Aviation Office (Luftfahrtbundesamt, LBA) to produce components using metal Additive Manufacturing. It has since been producing class 2 and 3 titanium serial parts by AM, delivering them under EASA Form 1.

Liebherr-Aerospace & Transportation is one of eleven divisional control companies within the Liebherr Group and coordinates all activities in the aerospace and transportation systems sectors. The company has more than five decades of experience supplying systems for the civil and military aviation industry, with the range of aviation equipment it produces including flight control and actuation systems, landing gear and air management systems, gears, gearboxes and electronics.

These systems are deployed in wide-bodied aircraft, single aisle and regional aircraft, business jets, combat aircraft, military transporters, military training aircraft, civil helicopters and combat helicopters. The aerospace and transportation systems division employs around 5,400 people and has four aviation equipment production plants at Lindenberg, Germany; Toulouse, France; Guaratinguetá, Brazil; and Nizhny Novgorod, Russia.