JEOL tabletop scanning electron microscopes for quality control in Additive Manufacturing

January 19, 2022

As the Additive Manufacturing industry grows, so does the demand for high-throughput scanning electron microscope (SEM) imaging and analysis techniques such as energy-dispersive X-ray spectroscopy (EDS). JEOL USA Inc, headquartered in Peabody, Massachusetts, USA, a wholly-owned subsidiary of JEOL Ltd. Japan, is a leading provider of these systems and has introduced a number of options suitable for the AM sector.

SEMs are powerful tools that reveal surface details at nanoscale resolution, explains JEOL. In quality control, these microscopes are useful for profiling structural, morphological and topographical characteristics. EDS goes a step further, providing compositional information from the X-rays produced when electron beams generated by tabletop electron microscopes interact with a specimen.

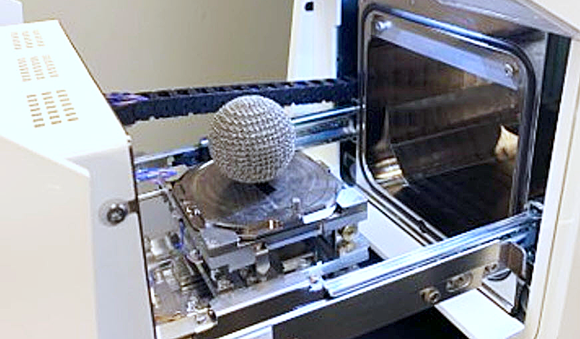

The JCM-7000 NeoScope™ is a benchtop SEM equipped with real-time 3D imaging, advanced auto functions and the option to add a fully embedded EDS with real-time analysis. The combination of high-resolution imaging and chemical analysis capabilities reputedly enables more detailed failure analysis than is achievable with optical microscopes alone. JEOL believes that the machine is suitable for AM producers, in that it can characterise size distribution, particle homogeneity and foreign contaminants to determine the purity of materials at nanometer scales.

With the growing complexity of industrial applications, manufacturers need QC processes that are fast, reliable and scalable. Manufacturers may opt for tabletop electron microscopes as they are easily calibrated to recognised standards, thus making it straightforward to repeat tests within a set of parameters.

Materials defects often occur at the nanometer scale, meaning a high degree of resolution is essential. SEMS use electrons instead of light to ‘see’ into materials. Since electron wavelengths are up to 100,000 times smaller than the wavelengths of visible light, electron microscopes resolve details hundreds of thousands of times smaller than optical microscopes.

Tabletop electron microscopes are also able to provide comprehensive chemical composition information when combined with EDS instruments. In quality control, for example, such a combination can help determine the thickness of coatings, the sizes of particles and grain boundaries.