Hexagon enhances its Additive Manufacturing offering with CADS Additive acquisition

July 5, 2023

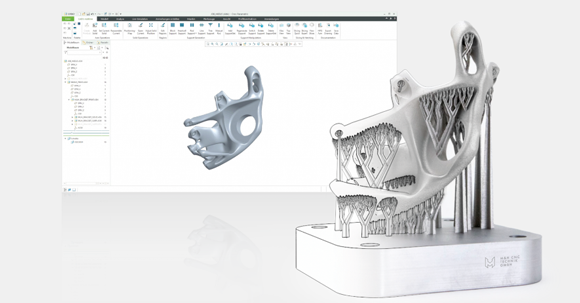

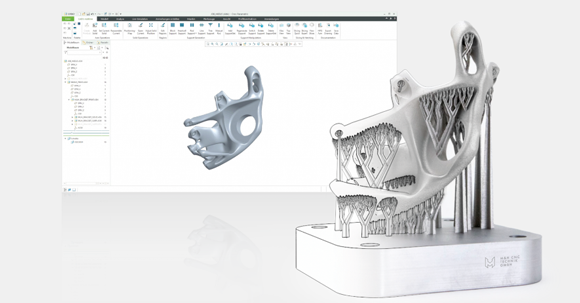

Hexagon AB, headquartered in Stockholm, Sweden, has completed the acquisition of CADS Additive GmbH, a provider of specialised software designed to help companies prepare designs for metal Additive Manufacturing. Developed for those using the Powder Bed Fusion (PBF) process, CADS Additive software reportedly guides users through the build preparation, helping turn design files into build instructions and improve manufacturing productivity.

CADS Additive, based in Perg, Austria, has been a partner of Hexagon since 2021, integrating its build preparation and support structure creation capabilities with Hexagon’s Simufact Additive process simulation software. Shared development roadmaps will reportedly look to further improve workflows, allowing users to adjust the orientation and support structure of their Additively Manufactured prints. This seeks to shorten the Additive Manufacturing workflow and provide easy steps to mitigate quality implications caused by changes to the orientation or support structure.

The AM Studio software from CADS Additive is reportedly already connected to Hexagon’s Nexus digital reality platform, completing Hexagon’s Nexus-enabled AM workflow by applying its extensive technology portfolio to computer aided design (CAD) model preparation, build preparation, simulation-based optimisations, quality and production intelligence, and the automation of computer aided manufacturing (CAM) to finish parts.

“Our investments reflect the growing importance of Additive Manufacturing, which has huge potential but has been held back by a fragmented ecosystem that means manufacturers are not getting the results they need fast enough. The acquisition of CADS Additive enables us to provide our customers with integrated tools that empower manufacturing teams to reduce waste and increase efficiency as they move from prototyping to production,” said Paolo Guglielmini, Hexagon President and CEO.

“Opening up the Nexus platform to our ecosystem partners and providing building blocks like CADS Additive helps customers improve their processes throughout the manufacturing value chain and realise the potential of industrial Additive Manufacturing,” Guglielmini added.

Download Metal AM magazine