GPM launches high-performance Al powders for wear-resistant AM

November 1, 2022

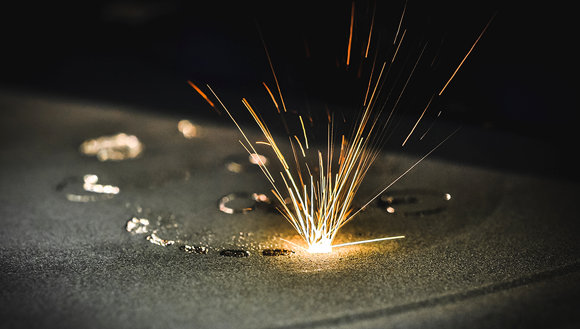

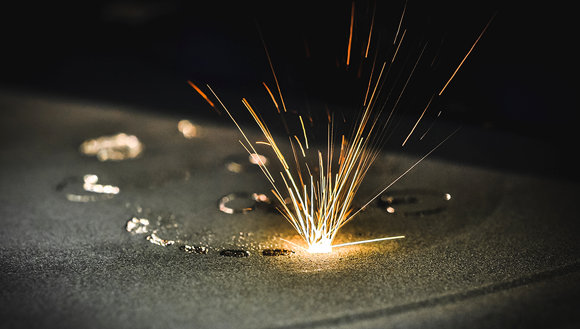

Gränges Powder Metallurgy (GPM), Velbert, Germany, a division of Sweden’s Gränges AB, has launched its second aluminium alloy aimed at the Additive Manufacturing sector. The high-performance aluminium alloy, S260 AM, is part of the company’s Dispal® range and is said to be characterised by high wear resistance and excellent tribology properties.

The fine matrix structure of silicon particles coupled with Cu and Mg elements is intended to allow users to manufacture components that are natively highly wear resistant. Because the silicon is evenly distributed across the part, the material’s performance is said to be long-lasting and permanent without the need for additional coating.

Another key characteristic of this material compared to other Dispal materials is a low coefficient of thermal expansion, also due to the high silicon content. This makes S260 AM well suited to components that need to be machined on very tight tolerances and need to perform in challenging environments where they are subjected to temperature fluctuations (e.g., oil pump gears). Spool valves can be manufactured directly with matching CTE to their manifolds and without additional manufacturing steps. Valves made of S260 AM can reportedly perform millions of cycles, outperforming steel valves.

“We saw a big need, especially in the automotive industry, for an alloy that is lightweight, wear resistant and at the same time has a low CTE,” stated Greta D’Angelo, Director of AM, GPM. “For many of our customers weight reduction is a big driver, and additive manufacturing allows them to go even further, without compromising on performance. Thanks to S260AM, our customers can break records and to do that more cost-effectively and with a shorter lead time.”

While S260 AM is another step for GPM into Additive Manufacturing, there are said to be plans for more material releases soon. Together with the development of new materials, GPM is working to address some of the main challenges that AM is still facing, such as serial production and high productivity.