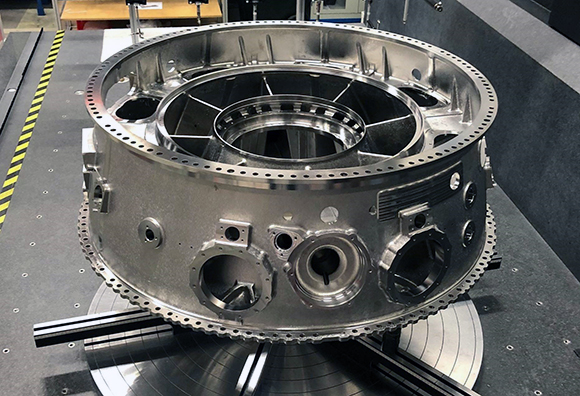

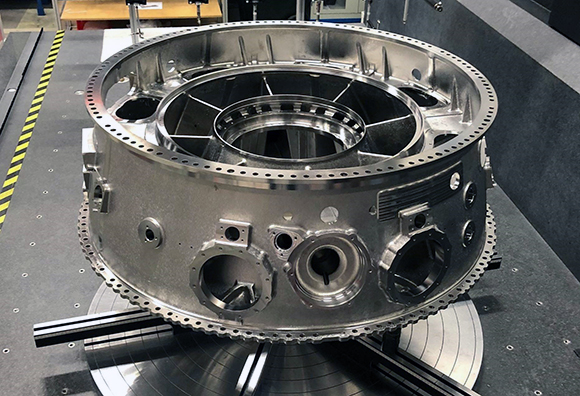

GKN Aerospace’s intermediate compressor case for Rolls-Royce UltraFan engine tested at full power

March 4, 2024

GKN Aerospace, a Rolls-Royce Core Partner in Clean Sky 2, has reported the successful testing of the UltraFan technology demonstrator incorporating the GKN-designed and manufactured Intermediate Compressor Case (ICC). The system was tested at full power at the Rolls-Royce facility in Derby, UK, with the initial phase of the test using 100% sustainable aviation fuel, underscoring a commitment to sustainable aviation practices.

Clean Sky 2 is a European aeronautics research programme dedicated to pioneering technologies aimed at reducing CO2 emissions and aircraft noise levels. Funded by the EU’s Horizon 2020 programme and Europe’s aviation industry, Clean Sky 2 aims to foster collaboration, global leadership, and enhanced competitiveness within the European aero industry.

The ICC is a critical structure between compressor modules and plays a vital role in carrying rotor loads to the engine casing and thrust mounts. GKN Aerospace’s developmental efforts encompass pioneering technologies – notably a low-cost, robust sectorised fabrication concept integrating castings. This process includes an advanced welding method based on precise computer simulations, optimised aerodynamics and acoustics for bleed system efficiency, a streamlined high curvature duct design, Additive Manufacturing of attaching parts, and model-based design methods.

Henrik Runnemalm, Vice President of GKN Aerospace’s Global Technology Centre in Sweden, shared, “The successful ground testing of the UltraFan engine signifies a significant milestone for our ICC. It underscores the success of the Clean Sky 2 collaboration and showcases our incorporation of cutting-edge sustainable technologies, such as additive fabrication, in ICC development. We take immense pride in partnering with the Rolls-Royce team to contribute to this energy-efficient aero-engine of the future.”

GKN Aerospace has received substantial support in Sweden for developing innovative manufacturing processes for the ICC. This support comes from the Vinnova-funded IntDemo-project and the Västra Götaland Region.

Download Metal AM magazine