GF AMotion Center invests in powder recycling solution for DMP Factory 500

October 27, 2021

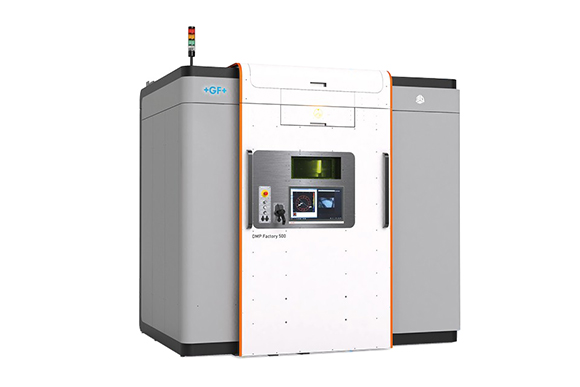

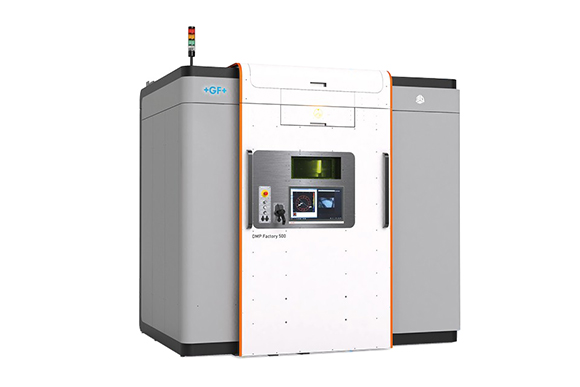

GF’s AMotion Center, located in Novazzano, Switzerland, reports that it has invested a six-digit amount in euros on new powder recycling technology. The new module optimises the manufacturing process and is intended to upgrade the DMP Factory 500.

The Powder Recycling Module (PRM) is the most recent of six components of the manufacturing system. It recycles the powder which was not fused by the lasers during the building process. The system fully automatically sieves surplus material allowing it to be reused in the next process step working in parallel with the Printer Module (PTM) without negatively impacting productivity. The recycling process is performed under an inert atmosphere in order to ensure the highest possible powder quality and mitigate the health & safety risks for operators.

The manufacturing solution consists of six function-specific modules: the Removable Print Module (RPM) is responsible for the powder and parts transport between the AM machine, Depowdering Module **(DPM) and PRM and thus ensures to always keep under control the raw material quality. The PTM is designed to withstand 24/7 production cycles with maximum AM machine uptime and performance.

The DPM automatically depowders the parts on the build platforms and the Transport Module (TRM) enables efficient transport of the RPMs reducing production time. The Parking Module (PAM) serves as storage for RPMs in a secured environment until they are ready for further processing. This optimally protects the powder inside the RPM from possible external influences such as oxidation.

The DMP Factory 500 modular AM platform is designed for the production of high-quality metal parts up to a dimension of 500 × 500 × 500 mm and is used to streamline workflows at what are said to be the lowest possible operating costs. The metal AM system was developed by GF Machining Solutions in partnership with 3D Systems and is being used at the GF AMotion Center for the production of parts for the aerospace and the energy market.