GeonX and IREPA Laser partner for simulation of large scale metal Additive Manufacturing

May 11, 2017

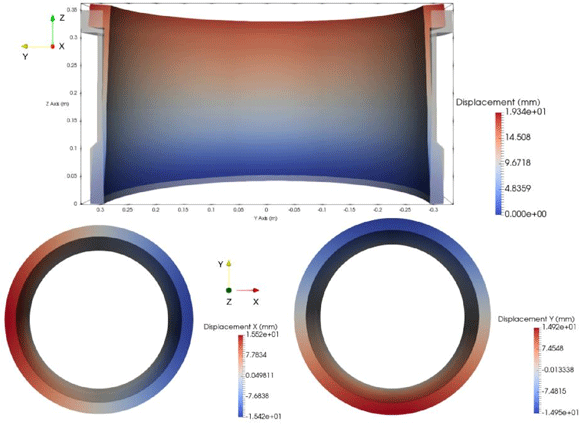

Results produced through process simulation with Virfac® (Courtesy GeonX)

GeonX SA, Gosselies, Belgium, has announced a new partnership with IREPA Laser, Illkirch-Graffenstaden, France. Under the partnership, the two companies will work together to use process simulation to predict distortion levels in large scale components manufactured by Laser Metal Deposition (LMD) Additive Manufacturing processes.

Predicting by means of simulations the level of distortions on large components manufactured by LMD is a challenging but often essential task. Reducing the number of trials and errors can lead to big savings of time and money, however the main challenge in simulation is the large computation time. GeonX states that it has addressed this challenge with the introduction of its latest Virfac® software, which uses original, intelligently optimised numerical methods to simulate manufacturing outcomes. According to the company, this has led to a large reduction in computation time, enabling the software to be used for industrial-scale simulations.

GeonX’s Virfac® software comprises an intuitive CAD-based user interface and parallel non-linear finite element thermo-mechanical-metallurgy solver for the simulation of Virtual Manufacturing processes in welding, machining, heat treatment, damage tolerance and Additive Manufacturing. By using simulation to reduce trial and error in large component manufacture, companies may be able to decrease cost and production time and minimise prototyping, project development and overall time to market.

A 650 mm diameter, 35 kg, titanium alloy cylinder produced by IREPA Laser (Courtesy GeonX)

In testing, the new Virfac® software was applied to a large cylindrical component manufactured by IREPA Laser. The 650 mm diameter, 35 kg, titanium alloy cylinder was simulated and compared against experimental measurements. According to GeonX and IREPA Laser, the results were in good agreement following a computation time of only around four hours.