GENOA 3DP simulation software integrated into ANSYS platform

June 28, 2018

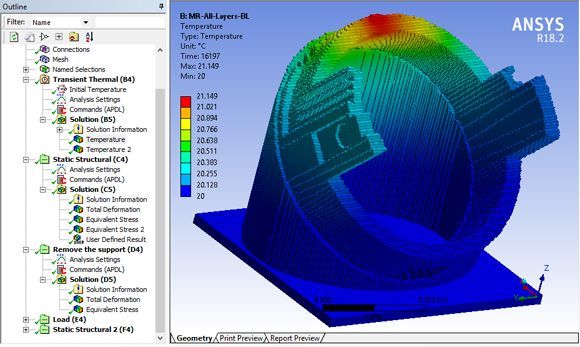

GENOA 3DP will now be fully integrated into ANSYS Workbench (Courtesy AlphaSTAR Corporation)

GENOA 3DP, an Additive Manufacturing simulation tool developed by AlphaSTAR Corporation, Long Beach, California, USA, will now be fully integrated into the software platform ANSYS Workbench, offered by ANSYS, Inc., Canonsburg, Pennsylvania, USA. GENOA 3DP can be used to accurately predict the deformation, residual stress, damage initiation and crack growth formation of as-built metal and polymer AM parts.

Using multi-scale progressive failure analysis methods to replicate the entire AM process, from material characterisation to advanced structural analysis, GENOA 3DP can determine voids, cracks and other manufacturing anomalies. The tool also provides end users with the ability to import a G-code file, generate a structural mesh, run test validated analysis and optimise the AM build while using the predictive tool within their own environment.

The AlphaSTAR team reported that it has been working for some time to prepare GENOA 3DP for integration with ANSYS Workbench. “We are answering the request of the industry,” stated Kay Matin, AlphaSTAR President. “With the full integration of ANSYS, we have broadened the scope of users that will have the ability to utilise the software”.

Some of the key benefits of GENOA 3DP are said to include:

- Process Simulations: High fidelity and low fidelity solutions for thermal and thermal-structural analysis

- Global & local FE mesh generator from G-code

- Environmental effects (e.g. oxidation) on material properties

- Scatter and uncertainty prediction

- Void and damage calculation using global/local material modeling with grain and grain boundary approach

- Post-build simulation

- Qualification and certification: as-built part performance prediction