GE Aerospace’s T901 rotorcraft engines with AM parts accepted for flight tests by US Army

October 17, 2023

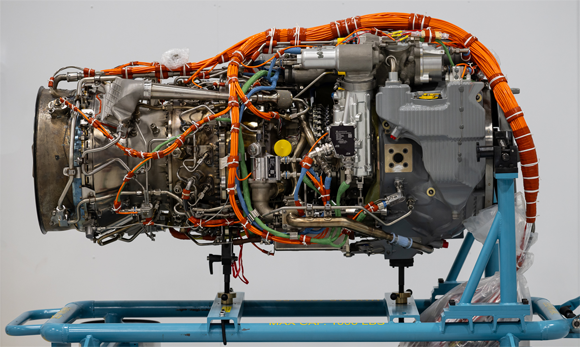

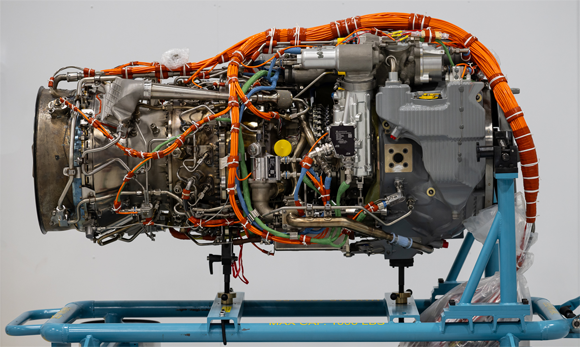

GE Aerospace, a subsidiary of General Electric, headquartered in Evendale, Ohio, has announced that two T901-GE-900 flight test engines have been accepted by the US Army to support the Future Attack Reconnaissance Aircraft (FARA) Competitive Prototype programme. The engine, featuring additively manufactured metal components, will power the UH-60 Black Hawk, AH-64 Apache, and FARA helicopters for the US Army.

The Defense Contract Management Agency officially accepted the next-generation rotorcraft engines at GE’s facility in Lynn, Massachusetts. As well as utilising the advantages of metal Additive Manufacturing, the T901 design draws on technologies such as 3D modelling and ceramic matrix composites (CMCs). This enables the engine to generate greater power while reducing weight.

“We are thrilled to announce the acceptance of the revolutionary T901 by the US Army,” shared Amy Gowder, president and CEO, Defense & Systems at GE Aerospace. “The performance, power, and reliability of the T901 – combined with GE’s decades of experience powering Army rotorcraft – will ensure our warfighters have a significant advantage on the battlefield.”

The T901 engine was developed by GE, leveraging its extensive experience in powering the Black Hawk and Apache helicopters with the T700 engine for over four decades, a design that clocked up over 100 million flight hours. The new T901 engine builds on this success, providing a 50% increase in power and a reduction in life cycle costs due to its simplified design and fewer parts. In addition, the engine’s fuel efficiency will improve the enduring fleet’s range, loiter time and fuel consumption, all while reducing maintenance and sustainment costs.

Another notable design feature of the T901 is its modular design, which is inherited from the T700 and a key factor in the T901’s low cost, growth, reliability, maintainability, and reduced life-cycle costs. By utilising this proven technology, the T901 can seamlessly integrate with the US Army’s existing helicopters while surpassing performance requirements.

Download Metal AM magazine