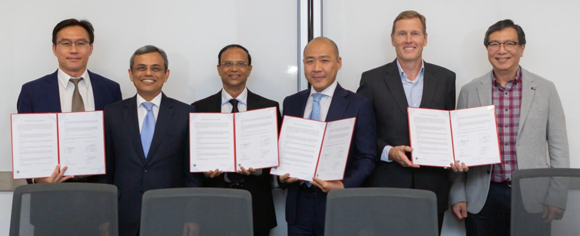

GE Additive signs MoU with Bralco Advanced Materials for Additive Manufacturing of magnetic parts

July 19, 2019

GE Additive has signed a Memorandum of Understanding (MoU) with research, product development and commercialisation company Bralco Advanced Materials Pte. Ltd., Singapore, for the development of metal additively manufactured magnetic components for applications in the aerospace, medical, automotive, energy, industrial automation and robotics industries.

The MoU aims to progress the AM of magnetic components in the Asia-Pacific region in particular. It is expected that Bralco’s strength in magnetic materials combined with GE Additive’s expertise in powder manufacturing and AM technology will enable the companies to accelerate the development of soft and hard magnets and components in complex shapes, with differentiated magnetic fields and high mechanical strength.

Such magnets could be capable of operating at elevated temperatures, high frequencies and high torque conditions, characteristics which would make them ideally suited for demanding applications such as in the traction motors of electric motors.

According to the companies, the MoU contemplates giving Bralco access to GE Additive’s AddWorks engineering consultancy team and its materials division, AP&C, potentially enabling Bralco to shorten its product development and commercialisation cycle. The MoU also contemplates the potential future appointment of Bralco as a service provider in the Asia-Pacific region for the production of parts and components using GE Additive machines and powders, based on Bralco’s magnetic materials compositions.

Amit Nanavati, Founder & CEO, Bralco Advanced Materials, stated, “Bralco is honoured to be working with GE Additive in this very exciting space of digital industry 4.0. This collaboration is a major milestone for us, coming at a time when the demand for soft and hard magnets is growing rapidly due to their use in every aspect of modern life, be it healthcare, mobility, personal communication devices, renewable energy or robotics.”

“We are very excited to set up our first R&D Lab and Product Innovation Centre in Singapore, fully equipped with a GE Additive machine and a state-of-the-art powder and built parts testing and characterisation lab,” he added. “We hope these steps will add to the growing importance of Singapore as a global centre for the Additive Manufacturing industry and as one of the most attractive locations to set up a high tech R&D facility.”