Fraunhofer ILT utilises AM for aerospace component gripper arm

September 13, 2021

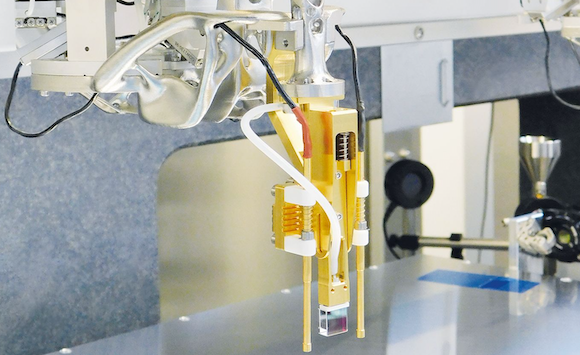

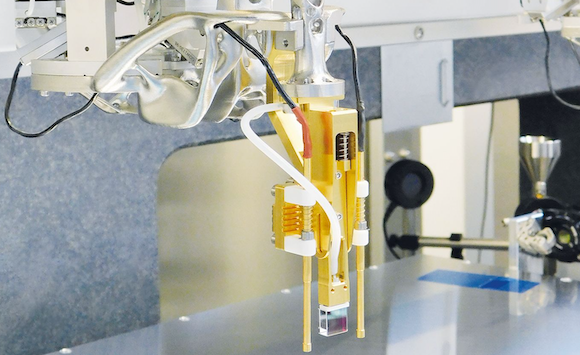

Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany, has developed a completely new topology-optimised gripper arm, manufactured via Laser Beam Powder Bed Fusion (PBF-LB), to improve the performance of a device used when assembling laser systems. Colleagues at the Chair for Digital Additive Production DAP at RWTH Aachen University also dimensioned the bionic structures in such a way that its payload could be increased, while having lower dead weight. Due to special post-processing, the gripper arm achieves cleanroom class ISO5.

In recent years, the assembly technology for laser systems qualified for space has been in development at Fraunhofer ILT, alongside partners such as DLR, Airbus Defence and Space, TESAT Spacecom and ESA. As all essential alignment steps are performed with manually guided robots, using the pick & align process, a central tool is the gripper arm. This sits on a hexapod and positions the components in the optical assembly with micrometre precision. There they are adjusted to within a few micro-radians and fixed in place by soldering. The design of the gripper arm is decisive for the precision of the assembly and determines how heavy the optical components can be.

Michael Janssen, who has been designing assembly grippers for years, stated, “With this technology, we are breaking new ground. We don’t first design the component and then check whether it has the desired properties – instead, we optimise the component geometry for the load scenarios.”

The new gripper will be used within the framework of FULAS – a universal technology platform developed by the Aachen researchers for building laser systems in aerospace projects. “We have incorporated the experience gained from the entire FULAS development into the production of the new gripper,” added project manager Heinrich Faidel from Fraunhofer ILT. A system based on FULAS is currently being built for the German-French climate mission MERLIN (Methane Remote Sensing Lidar Mission). The small MERLIN satellite is to be launched into space from Kourou, French Guiana, to map the distribution of methane in the Earth’s atmosphere. The satellite’s core component is a LIDAR laser that sends light pulses into the atmosphere and determines the methane concentration from the backscattered light.