Fraunhofer IFAM processes and tests new iron powder for Additive Manufacturing

July 11, 2019

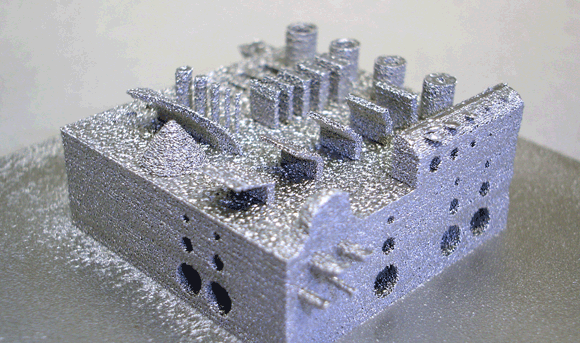

An iron powder demonstrator component designed by Agent-3D and produced by EB-PBF (Courtesy Fraunhofer IFAM)

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM), Dresden, Germany, reports that it has successfully processed and tested a new type of iron powder which it believes opens up new possibilities in metal Additive Manufacturing. With the production method, IFAM believes that prices for iron powder for AM can be achieved which are only around 10% of the current cost, and reports that there are also inexpensive alternatives for other materials, such as HDH titanium powder.

The institute stated that, until now, mainly spherical powders produced by inert gas atomisation have been used for the powder bed-based AM processes Electron Beam Powder Bed Fusion (EB-PBF) and Laser Powder Bed Fusion (L-PBF), resulting in high prices. However, the institute has now completed a feasability study in which it was able to produce dimensionally stable components by EB-PBF using its new iron powder.

Despite the more irregular particle shape and the expected poorer flowability of this iron powder compared to gas atomised powders, it offers a low-cost alternative, and has reportedly proven that the EB-PBF process is a robust technology with the ability to cope with variations in the flowability of the powder.

In addition to the various powder mixtures, IFAM stated that processing of a wide variety of alloys have also been successfully tested, and detailed investigations into the respective alloy behaviour have begun. The institute reports that it has also created an inexpensive alternative for the Additive Manufacturing of steels, which could also be conceivable for other materials.