Formalloy releases new L-series Additive Manufacturing machine

September 28, 2017

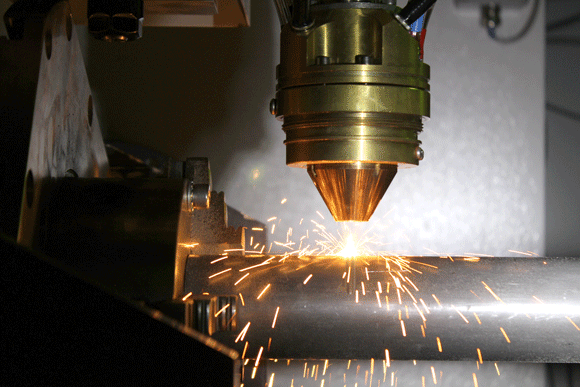

Formalloy’s Laser Metal Deposition technology is suitable for use in a number of industries

Additive Manufacturing company Formalloy, LLC, San Diego, California, USA, has released its L-222 Laser Metal Deposition machine, which includes an inert gas build chamber, scientific monitoring capability and the latest Blue Laser technology.

The new machine’s Blue Laser technology is from Nuburu Inc., Denver, Colorado, USA, and can reportedly be used to additively manufacture, repair and clad metallic parts more quickly and accurately than comparable processes. Formalloy is the said to be first company to perform Laser Metal Deposition with the new Blue Laser technology.

Compared to industry-standard IR wavelengths, blue laser absorption is said to be 3-20x better, resulting in process speed gains of 2-10x. Blue Lasers enable material processing capabilities which would either not be possible or produce low yields with IR. In addition, the ‘spot size’ of the laser is more than 5x smaller than IR, enabling greater precision, resolution and higher finish quality.

Formalloy’s Laser Metal Deposition technology is suitable for use in a number of industries including aerospace, oilfield, defence, automotive, chemical and heavy industry. Its L-series machines can be used with titanium, Inconel, stainless steels and other metals.