Fives Landis and AddUp produce stainless steel AM coolant nozzle

January 12, 2022

Fives Landis Corp., a precision grinding systems specialist and part of France’s Fives Group, has collaborated with AddUp, a metal Additive Manufacturing joint venture between Fives Group and Michelin, to design and produce a custom coolant nozzle.

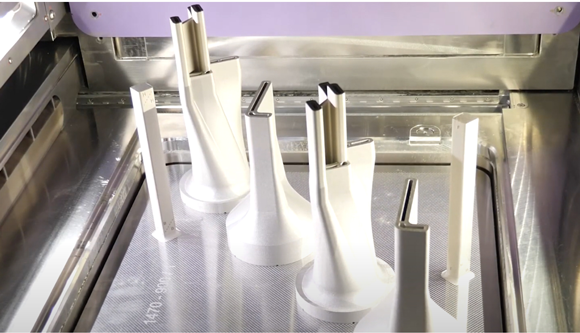

The nozzle design allows the flow position and shape to precisely match the challenging wheel geometry with fewer components in the assembly, while also providing optimum flow to the metal cutting zone in the grinding machine. This is said to increase the machine’s performance and optimises the grind cycle.

Fives explains that using traditional production processes, fabricating this complex part is difficult and requires multiple pieces and ideal interior geometries are impossible to create. Metal AM allows this type of nozzle component to be realised from the 3D digital design to the final additively manufactured metal part in only a few steps, in a matter of days, not weeks.

AddUp teams began by laying out the part in the 3D build preparation software, AddUp Manager, then developed the best manufacturing recipe for the build, including melt strategy and build orientation, before transferring the file to the AddUp FormUp 350 Powder Bed Fusion (PBF) machine where it was additively manufactured in stainless steel.

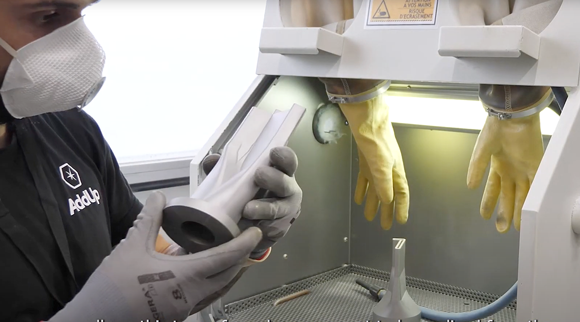

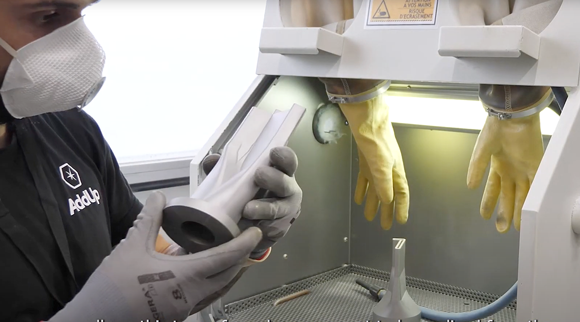

The postprocessing operations included stress relief, wire EDM and bead blasting to complete the part, making it ready for assembly on the grinding machine. The FormUp 350 achieves up to 0.1 mm dimensional accuracy and 99.99% material density. This is said to ensure accurate and repeatable part performance without failure.

The final result is a one-piece optimised coolant nozzle that accurately delivers coolant flow into precise locations, optimising the performance of the machine.