FIT Additive Manufacturing to add SPEE3D’s supersonic 3D deposition to its technology offering

September 18, 2018

The SP3D machine fires metal powders onto a defined spot on a material carrier at ‘three times the speed of sound’ to produce components without melting or heat (Courtesy SPEE3D)

FIT Additive Manufacturing Group, Lupburg, Germany, has purchased a supersonic 3D deposition (SP3D) machine produced by SPEE3D, Melbourne, Australia. According to SPEE3D, its machines can manufacture copper and other metal components in record time.

In an SP3D machine, metal powder is not spread over a surface but fired by a nozzle onto a defined spot on a material carrier. The powder particles hit that position at three times the speed of sound, with the corresponding kinetic energy, which binds them without the use of melting or heat.

The first SP3D machine will be installed by FIT late in 2018, initiating an extensive testing phase. Philip Emmerling, Research Engineer at FIT, stated, “We will focus on the functional performance of the components produced by this machine. Our first tests were promising, but much work has to be done.”

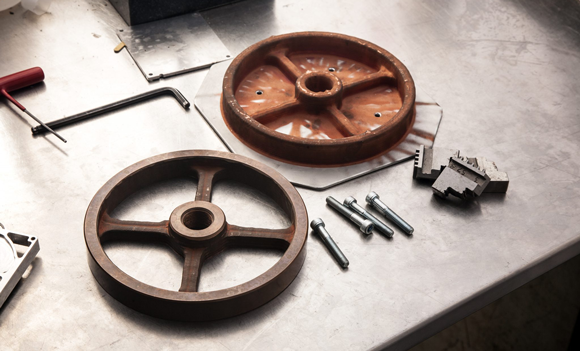

Components produced using SPEE3D’s supersonic 3D deposition process (Courtesy SPEE3D)

With its investment in this new type of system from SPEE3D, FIT aims to continue its transition from an additive manufacturer to a global AM research and development partner for industrial clients. “Fifteen years ago, we moved from service bureau to Additive Manufacturing with Electron Beam Melting technology. Five years ago, we started to support our clients with additive design challenges – mostly with powder bed technologies,” stated Carl Fruth, Founder and CEO of FIT AG.

“Now, new additive technologies and new players are emerging all the time. These need to be implemented on an industrial scale – independent from machine manufacturers – and we need to constantly scout the AM universe for new developments,” he concluded, while Albert Klein, CFO and CSO of FIT AG, added, “With this broad and deep approach we can support our clients in their extremely complex additive design and manufacturing problems. We are rapidly moving to additive technology partnerships rather than Additive Manufacturing.”