FIT Additive Manufacturing Group invests in HIP technology

April 30, 2019

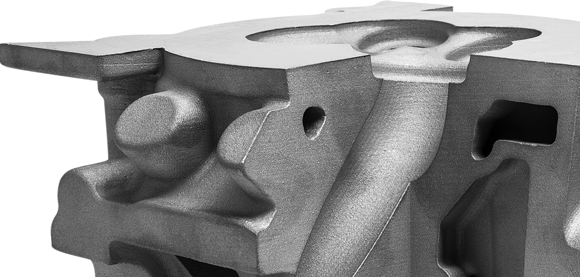

FIT Additive Manufacturing Group has invested in a HIP system from Quintus Technologies system (Courtesy FIT)

FIT Additive Manufacturing Group, Lupburg, Germany, has invested in the latest Hot Isostatic Pressing (HIP) system from Quintus Technologies, Västerås, Sweden. According to FIT, this decision was taken in order to better fulfill the quality requirements of AM serial metal parts, and it now relies on the combination of Additive Manufacturing and material-specific High-Pressure Heat Treatment (HPHT).

FIT specialises in the manufacturing of prototypes, production tools, AM spare parts, as well as additively manufactured end components for a variety of industries. The company states that HPHT services are expected to lead to a significantly higher part density and better overall quality and will be available from FIT as of September, 2019.

“We have evaluated the requirements of 250 international industrial customers for five years, and HIP turned out as an answer to many quality issues. The results that can be achieved by combining AM and HPHT are highly encouraging. It’s beyond all question that our customers will benefit strongly by this partnership. I even think that all Additive serial Manufacturing will experience a big boost when integrating HPHT as a post-processing service,” stated, Carl Fruth, CEO at FIT AG.

Jan Söderström, CEO at Quintus Technologies, commented, “We have high expectations in the industrialisation of HPHT post-processing by leading AM specialist FIT Additive Manufacturing Group. The overall optimisation of process parameters and material-specific heat treatment parameters in an in-line, lean-process production will lead to a new high-quality benchmark while reducing costs.”