Filamet adds metal to simple desktop 3D printing systems

July 15, 2016

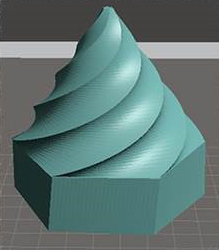

Sample CAD model

The Virtual Foundry, llc, headquartered in Madison, Wisconsin, USA, has developed a new metal based filament that it claims will allow any standard desktop 3d printer to produce metal parts. The company has combined traditional plastic 3D printing, Powder Metallurgy and Metal Injection Moulding processes to create Filamet™, a metallic filament that once printed and subjected to a sintering step, leaves a final product claimed to be over 99% pure metal.

Filamet™ has a composition of around 88% metal and 12% binding material. The sintering process removes the binder and bonds the metal particles together. Purchasing costs and operating costs are lower than existing metal systems and processing a Filamet™ print can be completed in less than five hours.

This example was prepared on the Makerbot desktop and printed on a Flashforge Creator Pro.

The company added that, if desired, users can avoid the sintering stage and simply print and polish a part to achieve a metallic finish, though without the properties of a sintered part.

“Printer manufacturers have struggled for years to bring 3D metal printers down into a workable price range. Filamet™ takes a different approach. Rather than bringing the high-end down, it extends the capabilities of current 3D Printers up to those of the high-end machines,” stated Bradley Woods of The Virtual Foundry.

The print is placed in a furnace to remove the binders then sinter the metal particles embedded in the print

“We expect materials to account for a large portion of near-term product innovation in the 3D Printing market. Our company offers an immediate solution to producing real and useful metal prints on the desktop 3D Printer that you already own,” added Woods.

Since introducing Filamet™, The Virtual Foundry has developed relationships with a number of industries. “We’re exploring small-scale manufacturing with Calvin Klein, low-cost consumable parts used in radiation therapy with the world’s largest nuclear medicine facility, a prototyping technique that will 3d print uranium (US Department of Energy), plus other materials used in aerospace and other industries.”

The final 3D print is 99+% Pure Metal

The company’s patented technology is claimed to work with any 3D Printer and any material that will sinter. Over the next six months there are plans to release filament based on other metals plus glass and ceramic materials.