FIA adds Scalmalloy to list of approved AM materials for Formula 1

July 2, 2020

The governing body of Formula 1®, the Fédération Internationale de l’Automobile (FIA), has added the high-strength aluminium alloy Scalmalloy® to its regulations as an officially approved Additive Manufacturing material for use in the championship, reports the alloy’s developer APWORKS GmbH, Taufkirchen, Germany.

Scalmalloy is an aluminium-magnesium-scandium alloy that offers high mechanical properties when processed by Additive Manufacturing. The alloy offers a very high tensile strength (UTS 520 MPa) and yield strength (480 MPa). Because of the low density of the material, it is reported to exhibit excellent specific properties, said to far exceed those of other aluminium alloys.

Scalmalloy also retains excellent ductility (elongation 13%) and is naturally very corrosion resistant as well as demonstrating a high degree of microstructural stability with respect to thermal ageing. Its unique combination of material properties has its origin in the fact that it was specifically developed for Additive Manufacturing, exploiting the characteristics of the manufacturing process.

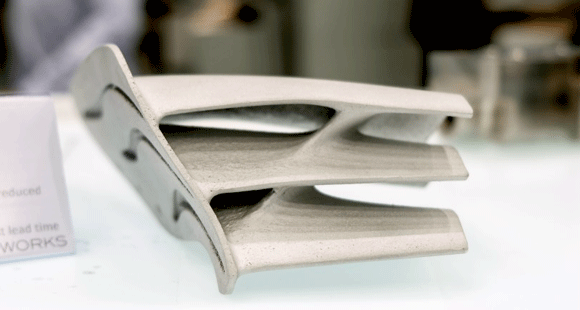

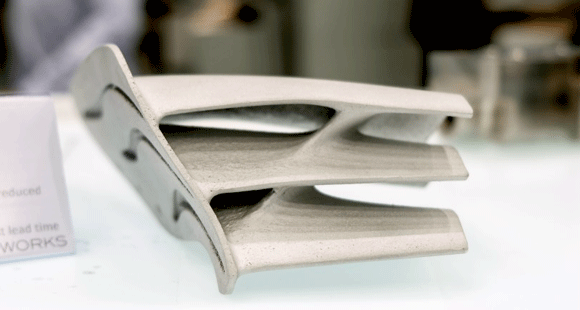

The material was developed by APWORKS and Airbus for aerospace applications, and is reported to be ideal for high-performance applications, especially in the motorsports industry, where its high strength and low density enable the production of topology-optimised lightweight structural components, which can enable better mass distribution to be achieved within the F1 regulation weight limit.

Coupling the material’s properties with the design freedom provided by AM can enable the production of high-performance parts with a level of functionality which might previously have been impossible to achieve.

“We are proud to see Scalmalloy in the list of approved materials,” stated Jonathan Meyer, Chief Product Officer at APWORKS. “Scalmalloy still stands head and shoulders above all other additively-processable aluminium alloys on the market, and due to its aerospace pedigree its performance is backed up by all the evidence necessary to give confidence in design.”

“Its extraordinary balance of strength, ductility and density makes it the material of choice in high-performance applications,” he continued. “We are already looking forward to broadening the applications further, as our Motorsport customers gain confidence to apply Scalmalloy® in increasingly critical applications.”

Want to know more about Scalmalloy®?

Read the article from APWORKS and TBGA in the Spring 2019 edition of Metal AM magazine.