Farsoon Technologies and Siemens China to collaborate on developing AM solutions

September 17, 2019

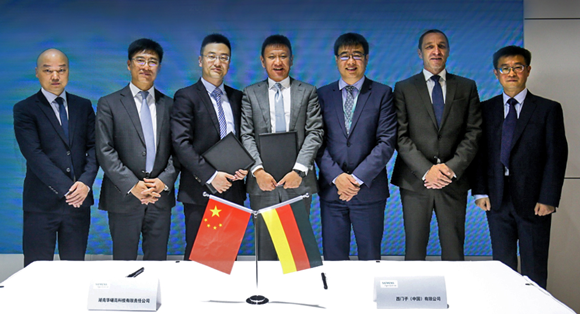

Farsoon Technologies, headquartered in Hunan, China, and Siemens Ltd., China, the Chinese division of Germany’s Siemens AG, have signed a collaboration agreement to produce industrial solutions for Additive Manufacturing. The agreement was signed during the 21st China International Industry Fair (CIIF). As part of the collaboration, the companies will reportedly implement Siemens’ end-to-end software and Digital Twin solutions with Farsoon’s open platform industrial AM systems.

Dr Xu Xiaoshu, Founder and CEO of Farsoon, stated, “We are very excited to start this collaboration with Siemens. Over the years, Farsoon has seen an increasing application of AM technology in the aerospace, industry manufacturing, medical, automotive and moulds. With joint efforts with Siemens, we will be able to offer high-performance and streamlined workflow AM solutions for industrial customers in China and overseas.”

“Additive technology is driving the next revolution of industrial manufacturing, it changes our mindsets from products design, manufacturing process to business models,” commented Wang Haibin, Executive Vice President of Siemens Ltd., China, and General Manager of Digital Industries Siemens Greater China. “We are glad to collaborate with Farsoon to expand the industrial applications of Additive Manufacturing.”