ExOne and Ford collaborate to achieve high-speed, high-density aluminium Binder Jetting process

March 12, 2021

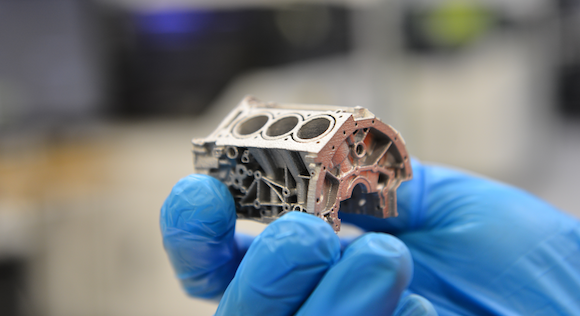

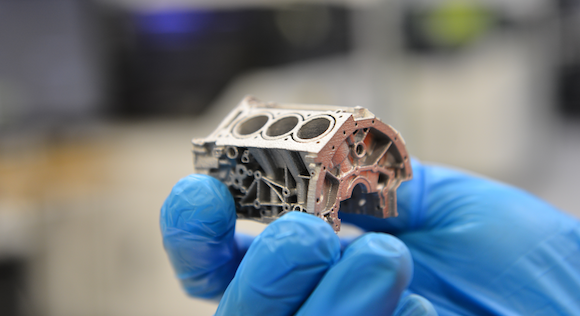

In a project co-funded by the ExOne Company, North Huntingdon, Pennsylvania, USA, and Ford Motor Company, a team of engineers, material scientists and manufacturing experts has developed a new patent-pending process for binder jet Additive Manufacturing and sintering of aluminium, which reportedly results in components with properties comparable to those found in die casting.

Although some aluminium alloys can be additively manufactured currently using lasers, the process developed by Ford and ExOne is reported to offer greater speed. The resulting process is expected to increase Ford’s efficiency, allowing the company to affordably manufacture complex parts designed for AM, which will enable size and weight reductions, part consolidation and performance improvements.

“Developing a fast, affordable, and easy way to 3D print aluminium with traditional material properties is a critical step toward light-weighting more products and delivering a more sustainable future,” stated John Hartner, CEO, ExOne. “Our world-class engineers and scientists are focused on solving the toughest problems with 3D printing technology, and this achievement is a real win for all of us.”

While the Binder Jetting process for sintering stainless steels was well understood, ExOne states that achieving densities higher than 99% for aluminium represents a significant achievement for the industry.

“This is a breakthrough in making 3D printed and sintered parts for the auto industry,” commented Harold Sears, Technical Leader for Additive Manufacturing, Ford. “While the 3D-printing process is very different than stamping body panels, we understand the behaviour of aluminium better today, as well as its value in light-weighting vehicles. High-speed aluminium 3D printing paves the way for other opportunities that we’re just now starting to take a look at because of the ability to do complex parts with aluminium that previously weren’t possible. It’s really opening doors for other opportunities.”

The relationship between ExOne and Ford dates back to the early 2000s, when Ford purchased several of ExOne’s first industrial sand AM machines in the US in order to create sand moulds and cores for metal casting. The joint development process of this aluminium process began in 2019, with Ford leading the final material and repeatability testing to verify accuracy. The Ford/ExOne team is actively working on designs to further utilise the process and resulting materials.