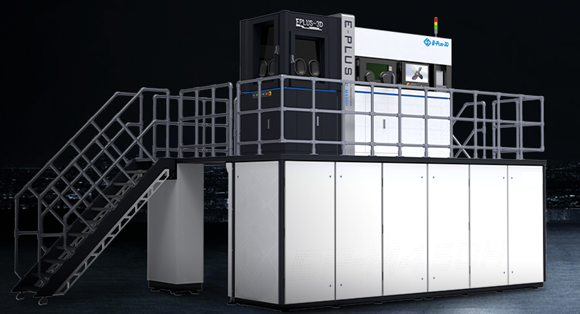

Eplus3D launches its tallest metal Additive Manufacturing machine

January 19, 2022

Eplus3D, headquartered in Hangzhou, China, has launched the EP-M450H, a Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machine with a build chamber measuring 455 x 455 x 1100 mm, for use in aerospace, aviation, automotive and defence applications.

The EP-M450H can operate with a variety of metal powders such as titanium, aluminium, nickel, and copper alloys; stainless steel and maraging steel; and cobalt chrome. The system features a bi-directional powder re-coating method which can lead to a reduced re-coating time and repeatable positional accuracy along Z-axis of building direction ≤±5 μm.

There is a dual laser system with two 500 W fibre lasers. The overlapping deviation between the two is ≤±0.1 mm, meaning the overall mechanical properties are comparable to parts built with a single laser machine. The build rate for the machine is up to 55 cm3/h, with density up to 99.9% and <5% deviation in mechanical properties.

The sustained monitoring of powder left in the feeder, and the ability to add powder without stopping the machine, enables uninterrupted part building during which a real-time display is available for various sensors.

Reduced gas consumption during build time, ≤6 litres/min, helps to lower operation cost, while the blow back enabled filtration system is intended to remain active for over 1,000 hours.

The integrated process software offers the ability to divide the build model into different sections, for which process parameters can be individually applied. This can be integrated with Siemens NX software to realise design planning as part of the same system.