Eplus3D launches customisable EP-M400S Additive Manufacturing machine

February 1, 2024

Eplus3D, headquartered in Hangzhou, China, has announced the launch of its EP-M400S metal Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machine. This new machine is an enhanced version of the EP-M400 and offers greater flexibility and improved performance.

A high level of customisation is possible with the new EP-M400S. There is the option for one, two, three or four lasers and, with multiple power levels (500 W, 700 W or 1 KW for each laser), users can fine-tune the performance to meet specific needs.

The EP-M400S features a top-feeding powder hopper and bi-directional powder re-coating, reducing dosing time by up to 30%. This approach is said to streamline the metal powder layering process, leading to substantial time savings, making the EP-M400S a more efficient system and close-loop powder circulation.

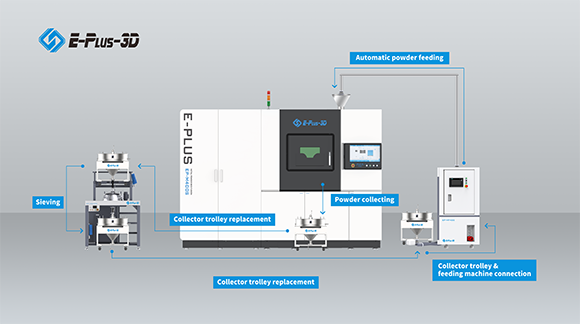

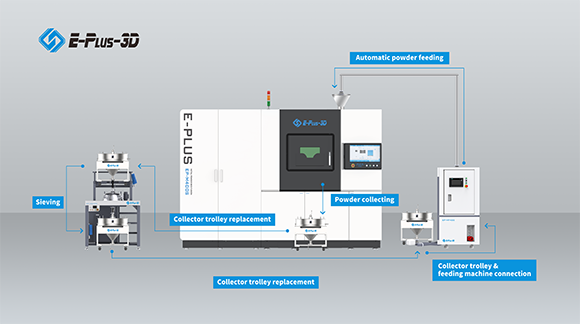

The EP-M400S is fully compatible with accessories such as Eplus3D’s ultrasonic sieving machine EP-MS600 and automated powder feeding system EP-MF400. The EP-M400S enables seamless integration and the ability to refill the powder tank without interrupting the manufacturing process, saving valuable time, and preserving powder conditions within an inert atmosphere.

The new design, resulting in a 10% reduction in size compared to its previous versions, includes added features that make cleaning and maintenance easier, improving both functionality and serviceability of the machine.

Retaining the layer thickness and material compatibility of its predecessor, the EP-M400S is suitable for multiple industries, including aerospace, automotive, moulding, and medical implants.

Download Metal AM magazine