EOS releases NickelAlloy HAYNES 282 for M290 and M400-4 machines

July 8, 2022

EOS GmbH, headquartered in Krailling, Germany, has introduced EOS NickelAlloy HAYNES® 282®for its EOS M290 and EOS M400-4 Additive Manufacturing machines. The material is a precipitation-strengthened nickel-base superalloy with a combination of high temperature strength, thermal stability and fabricability. Typical applications for the material include aerospace and rocket engine components, turbomachinery and gas turbine parts and energy industry components.

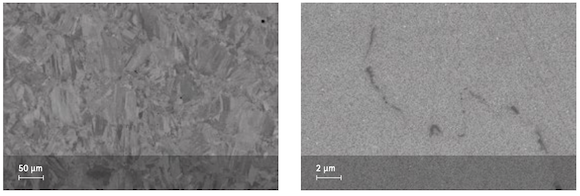

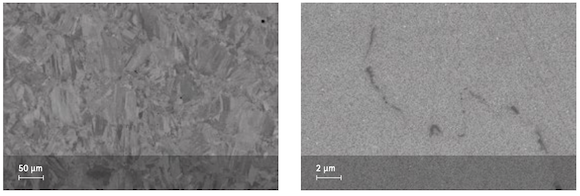

In as-built condition, EOS NickelAlloy HAYNES 282, reputedly has low strength and high ductility. Solution and ageing heat treatments are required to produce the microstructure and strengthening phases for high temperature performance.

EOS has characterised two heat treatment options: (1) recrystallisation solution treatment & standard two-step ageing and (2) standard solution & standard two-step ageing. Heat treatment Option 1 is recommended for properties closest to wrought HAYNES 282.