EOS expands production capacity with move to new plant

February 1, 2018

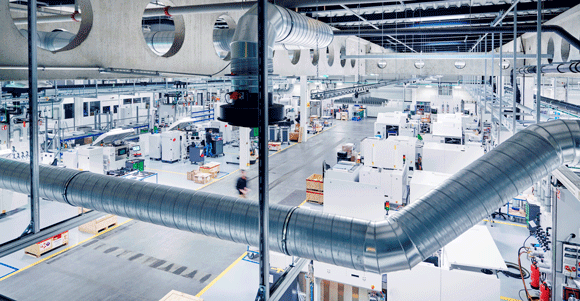

The new EOS manufacturing site in Maisach, Germany (Source: EOS)

EOS GmbH has expanded its production capacity and relocated its system manufacturing facilities to a new facility in Maisach-Gerlinden, near Munich, Germany. The new 9000 m2 factory will allow EOS to boost its production capacity up to around 1,000 systems per year.

Commenting on the announcement, Nikolai Zaepernick, Senior Vice President Central Europe at EOS, stated, “Our technology is the right choice for high-quality series manufacturing applications. Industrial 3D printing has arrived in manufacturing. We installed around 1,000 systems in the first ten years of our existence as a company, this number has increased significantly, particularly during the last two years.”

EOS is reported to have an installed base of around 3,000 Additive Manufacturing systems worldwide. “Over the next few years we also expect to see a further significant demand for our technology,” added Zaepernick.

As the quality of materials, processes, and systems is a top priority for many markets with high quality standards such as the aerospace, medical technology, or automotive sectors, EOS supports the qualification of the technology at its customers’ premises. In turn, this is said to help shorten the time to market for additively manufactured products.

When a customer buys a system from EOS, factory acceptance tests (FATs) are carried out. At the new plant in Maisach, customers also have the opportunity to get involved in the acceptance tests of new systems. In addition to the machine qualification customarily performed by EOS, customers can request to have specific test jobs built of parts that they actually want to produce at a later date.