Digital Metal adds pure copper to its metals range

February 25, 2021

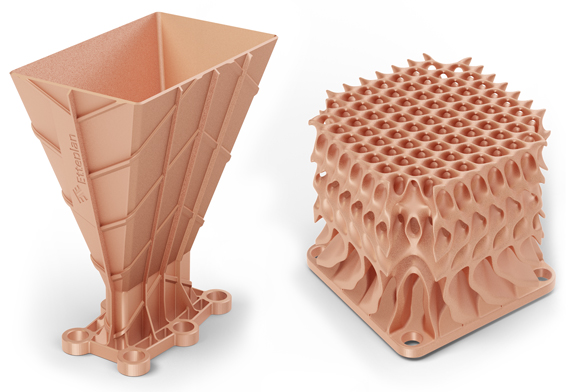

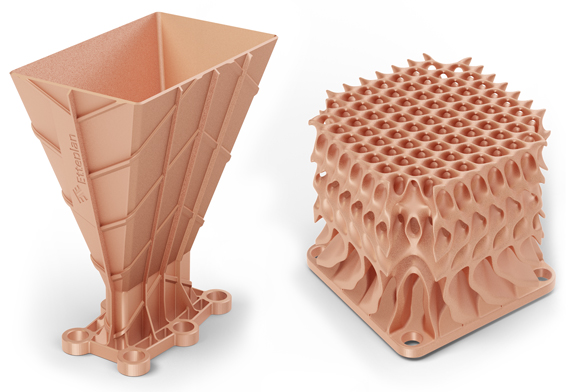

Digital Metal, part of Sweden’s Höganäs group and a global supplier of high-precision metal Binder Jetting (BJT) Additive Manufacturing systems for industrial use has added pure copper, DM Cu, to its material offering.

The excellent thermal and electrical conductivity of pure copper make it perfect for a wide range of applications, from electronics to heat exchangers, heat sinks and engine parts. Additively manufacturing parts in copper also offers a new freedom for designers, allowing optimal functionality with few restrictions. Copper is also known for being antibacterial.

For its customers, Digital Metal believes it will see the benefit of additively manufacturing with 99.9% pure copper versus more traditional copper alloys used in laser-based systems.

“Printing with pure copper using Digital Metal’s Binder Jetting technology is one of the most anticipated material launches ever, and totally new within binder jetting. Copper has been high up on our customers’ wish list and timing is perfect with the demand for copper applications soaring in fast growth areas such as e-mobility and heat conductivity,” stated Christian Lönne, CEO.

“We have been developing the process for some time internally, but I would really like to emphasise the value of the excellent cooperation with key customers in our fast-growing Digital Metal User Group,” he continued. “It has been a great help and we are now very pleased to deliver a high-quality copper process for Digital Metal Binder Jetting.”

DM Cu pure copper is the latest addition to Digital Metal’s BJT system, other materials featured in the company’s range include stainless steel 316L and 17-4PH, tool steel DM D2, superalloys DM 625 (equivalent to Inconel 625) and DM 247 (equivalent to MAR M247) and titanium Ti6Al4V.