Desktop Metal and Uniformity Labs announce new aluminium powder for use in Binder Jetting

March 11, 2021

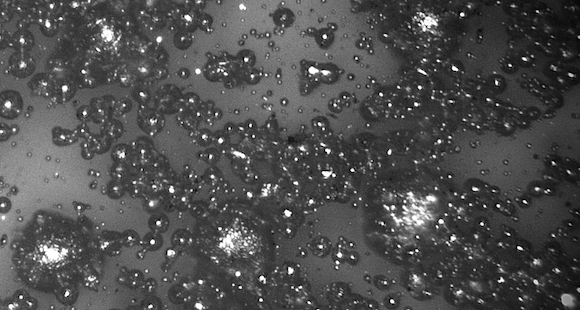

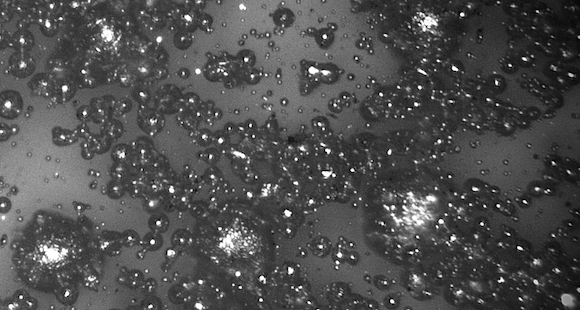

Through a collaboration between Desktop Metal, Burlington, Massachusetts, USA, and Uniformity Labs, Fremont, California, a new powder enabling aluminium sintering for Binder Jetting (BJT) AM technology has been discovered. The news follows a multi-year effort between the companies to develop a low-cost raw material that yields fully dense, sinterable 6061 aluminium with greater than 10% elongation, as well as improved yield strength and ultimate tensile strength versus wrought 6061 aluminium undergoing comparable heat treatments.

“This breakthrough represents a major milestone in the development of aluminium for Binder Jetting and a significant step forward for the AM industry, as it is one of the most sought-after materials for use in automotive, aerospace and consumer electronics,” stated Ric Fulop, CEO and co-founder of Desktop Metal. “The global aluminium castings market is more than $50 billion per year, and it is ripe for disruption with Binder Jetting AM solutions.”

“The introduction of lightweight metals to Binder Jetting opens the door to a wide variety of thermal and structural applications across industries,” added Adam Hopkins, founder and CEO of Uniformity Labs. “This innovation is a key step towards the adoption of mass-produced printed aluminium parts.”

This new powder, Uniformity 6061, enables the sintering of unadulterated 6061 aluminium, said to be a significant improvement over prior aluminium sintering techniques, which required coating powder particles, mixing sintering aids into the powders, using binders containing expensive nanoparticles or diluting the aluminium with metals such as lead, tin or magnesium. Most importantly, Uniformity 6061 also allows for the use of water-based binders and has a higher minimum energy relative to other commercially-available 6061 aluminium powders, resulting in an improved safety profile.

Over the coming year, Desktop Metal and Uniformity Labs will continue their partnership to qualify the powder and scale production for commercial release. Once fully qualified, Uniformity 6061 will be available for use with the Desktop Metal Production System.

Fulop concluded, “These are the best reported properties we are aware of for a sintered 6061 aluminium powder, and we are excited to make this material available exclusively to Desktop Metal customers as part of our ongoing partnership with Uniformity Labs.”