Context releases ‘AM3DP Materials Utilisation Report’, showing high growth for Additive Manufacturing

June 10, 2019

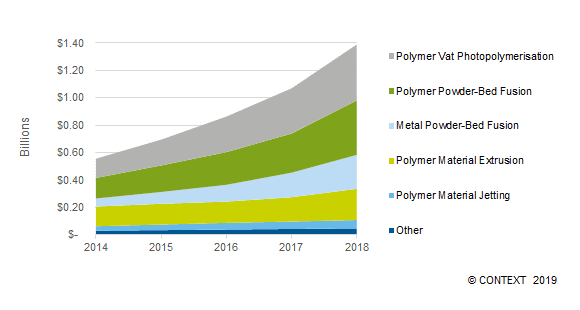

Five-year global industrial materials utilisation revenues by material and process (Courtesy Context)

Context, a supplier of market intelligence and analytics headquartered in London, UK, has released its ‘AM3DP Materials Utilisation Report’, which examines the Additive Manufacturing materials market in order to reveal quarter-by-quarter utilisation of materials by machine type, process, core-material, sub-material end-market, and principal use, allowing users to examine the entire global market as well as individual processes and end-markets.

The report divides material types for each process into key subgroups for AM, with the metal subgroups analysed including aluminium, cobalt-chrome, nickel alloys, precious metals, steels and titanium. Wax, ceramics, sand, biological materials, and all polymer materials are also covered by the report.

According to the company’s report, revenues from materials for industrial Additive Manufacturing systems have surged by $4.6 billion over the past five years, with 29.9% year-on-year growth in 2018. From its findings, Context believes that the market looks set to better the 2013–2018 five-year compound annual growth rate (CAGR) of 25.98% and is expected to amass another $15 billion over the next five years.

The report also reveals that from 2014 to 2018, 80.6% of global revenues for materials used in industrial systems came from polymers, while metals accounted for 13.5%. However, the latter’s share increased to 17.9% in 2018 while polymers’ dipped to 78.8%, highlighting the growing momentum of metal Additive Manufacturing.