Concept Laser’s new software offers full control of parameter settings

October 20, 2016

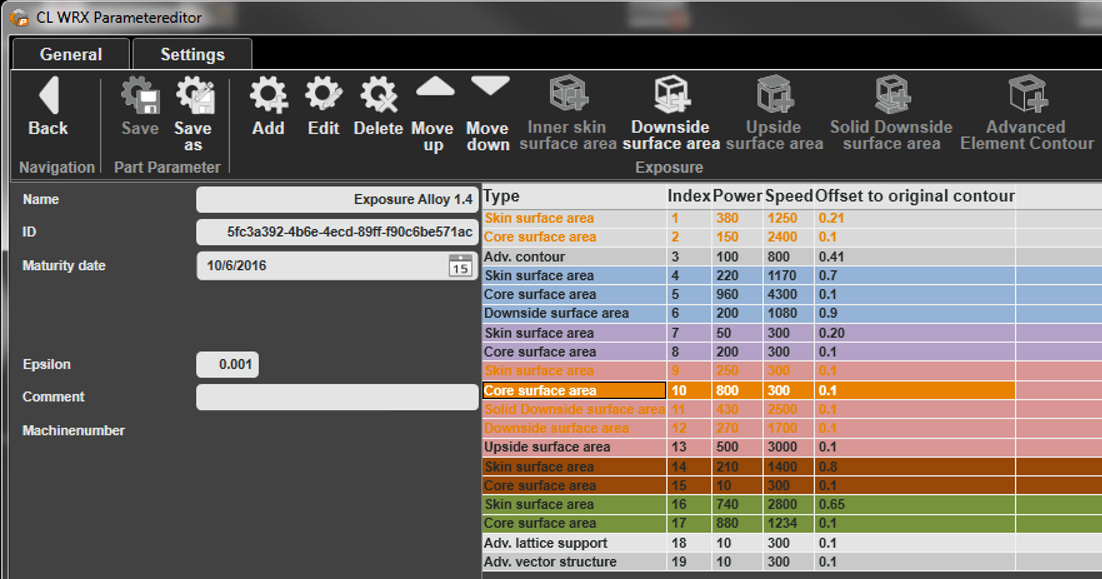

The CL WRX Parameter software allows all setting characteristics for a parameter to be viewed and edited (Courtesy Concept Laser)

Concept Laser, Lichtenfels, Germany, is now offering advanced users of its AM machines the option to view and freely modify all parameter characteristics through its CL WRX Parameter system. The software is directed towards users from research institutions and industry, in particular from the aerospace and medical technology sectors, where the ability to view and adjust all parameters can help in the qualification of new materials or products.

The CL WRX Parameter software provides the same tools that the development department at Concept Laser uses to develop parameters. The software can be stored on a PC and can thus be edited directly. For all material acquired from Concept Laser the customer optionally receives the speed parameter or quality parameter completely open and for individual adjustment, as far as available. The user can now also obtain further parameters in each case.

“CL WRX Parameter gives us the freedom to optimise our Additive Manufacturing for specific customers and applications and thus exploit the technology to its full potential. This allows us to manufacture products for the medical technology and aviation sectors to the highest quality standards and with qualified processes,” stated Eric Wycisk, Technical Director of Bionic Production in Hamburg. Before the user can utilise CL WRX Parameter Concept Laser states that training from the company is absolutely essential. The complex relationships between the parameter options must be explained in order to avoid possible damage caused by incorrect settings in subsequent handling.