CGTech celebrates 35 years of simulation

January 30, 2023

CGTech, Irvine, California, USA, developer of the Vericut machine simulation software, is celebrating thirty-five years in the industry.

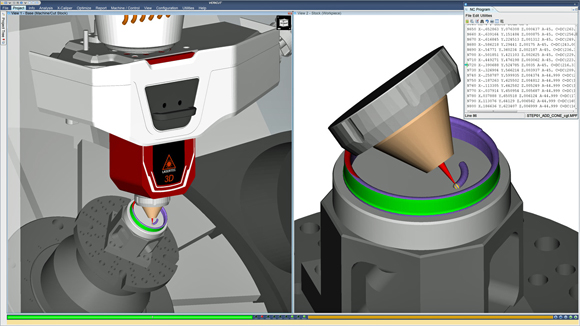

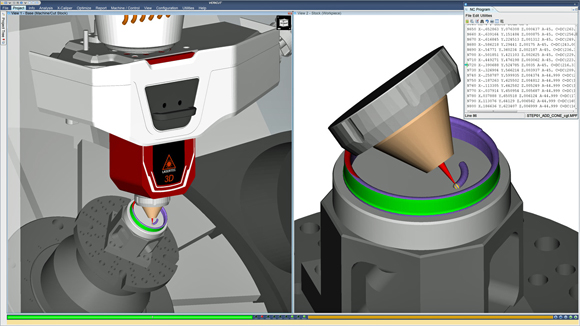

“Whether it’s milling, turning, mill-turning or any other CNC-machining, Vericut is the industry standard to simulate CNC machines, as well as optimise and verify NC programs,” stated Margaret Schmitt, president of CGTech.

“For 35 years, CGTech’s technology leadership and experienced team have helped Vericut evolve together with our customer base,” she continued. “CGTech’s solutions are deeply entrenched in the aerospace industry’s history, and adopted today across industries ranging from oil & gas to Formula 1 racing. People are at the heart of CGTech’s success and have made it what it is today: an innovative software company driven by team spirit and customer care.”

CGTech was founded by Jon Prun in 1988, stemming from the need to verify NC tool path programs without taking machining time to prove-out a part. Vericut is reputed to be the first widely available method to test machine tool paths in a virtual environment and has since expanded its original capabilities to include physics-based optimisation with its Force module, composites programming and simulation, as well as Additive Manufacturing and hybrid processes.

Vericut was developed in house by software engineers and leaders experienced in manufacturing and the CAD/CAM space. Improvements are made with each release in an effort to support complex multi-axis kinematics, further reduce cycle times, increase tool life, and further optimise the simulation. New features are also being developed, including live CNC machine monitoring features, tool performance optimisation, and more.

“In my thirty plus years with CGTech it has been amazing to see this company grow globally, to satisfy even the most demanding NC manufacturing needs. I’m so proud to be part of the abundantly knowledgeable and creative staff at CGTech,” added Gene Granata, Director of Product Management. “Together, we truly enjoy applying our collective experience supporting our valued customers, helping them be more competitive and create parts as efficiently and safely as possible.”

CGTech has offices located in the United Kingdom, France, Germany, Italy, Japan, China, Singapore, India, Brazil, and Korea to support its customer base. The company hosts local Vericut User Exchange (VUE) meetings annually across the globe to connect with customers to support their growth and needs.

CGTech is focused on to strengthening its offers in verification and optimisation, as well extending upstream to post-processing through the recent addition of ICAM Technologies Corporation to Sandvik, and downstream to connectivity using real-world machining data and performance.

Download Metal AM magazine