BOFA releases upgraded filtration system to boost metal AM productivity

September 13, 2021

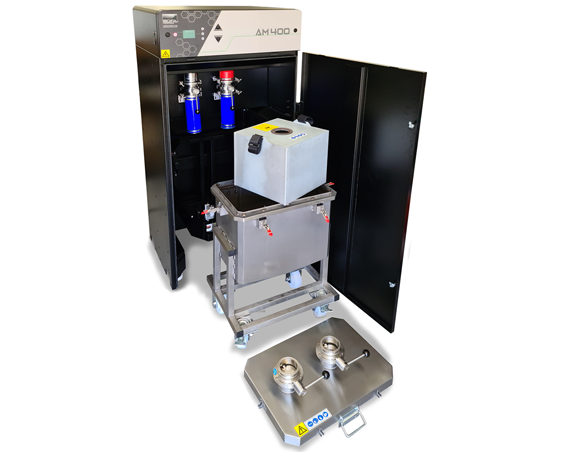

BOFA International, Ltd, a global fume and dust extraction solutions provider headquartered in Poole, Dorset, UK, has developed a new system intended to make the exchange of filters in metal Additive Manufacturing processes safer and faster. The new stand-alone AM 400 system uses patented technology that enables the filters that remove potentially harmful fumes, gases and particulate from metal AM machines to be exchanged on site without risking a thermal event.

The Laser Beam Powder Bed Fusion (PBF-LB) process must operate in an inert atmosphere, because the materials worked risk spontaneous ignition should they come into contact with oxygen. As a consequence, when new filters were needed for these systems, equipment had to be shut down and moved to a safe area for the saturated filters to be removed and replaced by operatives wearing full PPE. In BOFA’s AM 400, however, filters are contained within a separate housing with a robust seal, enabling filter exchange in what is said to be a quicker and safer way without the need to isolate the AM machine.

Haydn Knight, Sales & Marketing Director at BOFA, stated, “This innovation in filtration design will lead to significant productivity gains for businesses involved in metal Additive Manufacturing. This production process is used across multiple industry sectors to create high-value components and products, and, by enabling easier and safer filter exchange, end users are able to benefit from reduced downtimes, which translates into tangible productivity gains.”

The AM 400 extraction system has been developed specifically for the metal AM market, offering high air flow potential up to a maximum flow of 5.4 m3/min and a maximum operating pressure of 250 mBar, with low leakage at <30 ml/min @ -10 mBar. System users may also benefit from changes that optimise filter performance, enabling operators to monitor filter status and coordinate exchanges to match maintenance schedules.

Knight concluded, “The AM 400 marks a significant advancement in extraction technology for metal Additive Manufacturing through a design that helps safeguard human health and product quality, while delivering value-adding productivity improvements.”