BOFA paper underscores need for filtration in Additive Manufacturing

April 5, 2022

Despite the growth of Additive Manufacturing technology, there is relatively little authoritative industry insight into the by-products of Additive Manufacturing processes. Research undertaken by BOFA International, Ltd, headquartered in Poole, Dorset, UK, is intended to underscore how filtration and atmosphere management can contribute positively to workplace environmental practices while helping drive productivity.

The full paper ‘3D printing emissions: The basics’ is available here for download.

“The term ‘3D printing’ covers many Additive Manufacturing processes but they share a need for effective removal of particulate and fume to help operators meet their obligations under Occupational Safety and Health Administration regulations,” stated Katrina Clemens, General Manager, BOFA Americas, Inc.

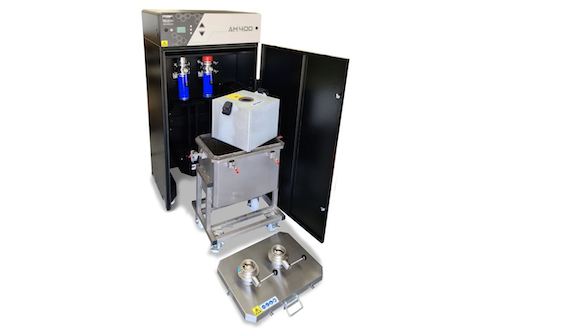

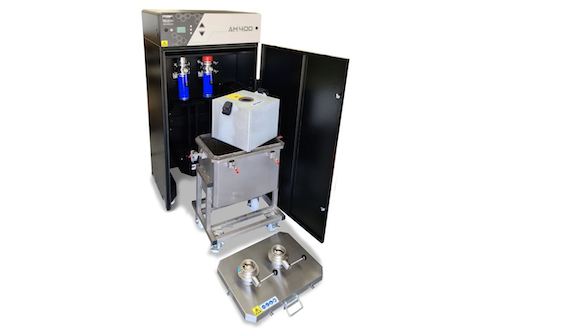

“BOFA’s portable range of extraction units for this sector also helps filter print residue that would otherwise build-up on expensive machinery,” Clemens continued. “In time, this debris could potentially degrade high-value components, affect product quality and impact productivity.”

BOFA intends to aid manufacturers to manage their Additive Manufacturing environments using advanced filtration. The company’s range of portable filtration and atmosphere management systems are tailored to specific processes and provide multi-stage filtration of nanoparticles, particulate, fume and gases.

BOFA’s filtration and extraction solutions will be on display at the RAPID+TCT 2022 event in Detroit, Michigan, USA, which is scheduled to take place May 17–19.