Boeing and Norsk Titanium recognised for metal additively manufactured structural components

January 25, 2018

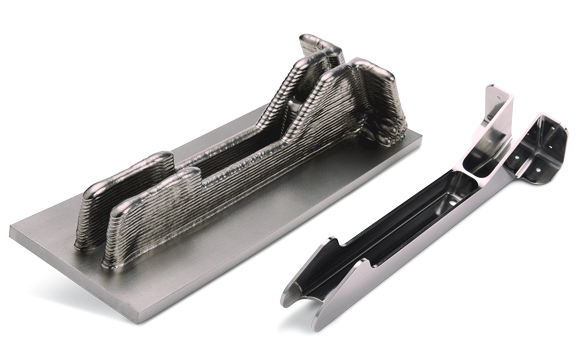

Norsk Titanium and Boeing qualified the first AM structural titanium parts for a commercial aircraft in 2017 (Courtesy Norsk Titanium)

Boeing and Norsk Titanium have been selected as one of the winners of Aviation Week & Space Technology’s 61st Annual Laureate Awards, in the category of Commercial, Supplier Innovation, in recognition of the companies’ qualification of the first structural titanium parts for a commercial aircraft made using Additive Manufacturing.

According to the organisers, the awards honour ‘extraordinary achievements in the global aerospace arena.’ The winners of the 2018 Laureate Awards will be honoured on March 1, 2018, at the National Building Museum in Washington, DC, USA, at which time a Grand Laureate will be announced in each of the four categories.

John Andersen, Norsk Titanium Chairman & CEO, commented, “We are honoured to be recognised for our work with Boeing to achieve this milestone. The Aviation Week Network’s Laureates Awards have a long history of recognising the very best in the industry and we are thrilled to win this distinction.”

Norsk stated that it received its first production order from Boeing Commercial Airplanes for the Additive Manufacturing of structural titanium components for the 787 Dreamliner earlier this year. “The delivery of these first parts represents significant progress for Additive Manufacturing,” commented Andersen. “Qualification with the OEM, certification with the FAA, and the ability to transition to production and meet customer cost, quality and delivery expectations.”

Norsk received its first production order from Boeing Commercial Airplanes for AM components for the 787 Dreamliner earlier this year (Courtesy Norsk Titanium)

“Norsk Titanium delivering on a significantly reduced timeline further signals the ancillary cost benefits that customers may realise with Additive Manufacturing,” he continued, “lead time reduction, lower inventory requirements, and future spare parts continuity assurances.”

“Additive Manufacturing is a highly disruptive capability that will support Boeing’s success in our second century of aerospace innovation,” added Kim Smith, Boeing Commercial Airplanes Fabrication Vice President and General Manager and Boeing Additive Manufacturing Leader. “By working closely with the FAA and our suppliers, Boeing is forging a path for the design and certification of additively manufactured flyaway parts for the aerospace industry. This technology will enable us to offer our customers more cost competitive products customized to meet their needs, faster than ever before.”

Joseph C Anselmo, Editor-in-Chief of Aviation Week & Space Technology, stated, “Boeing, Norsk Titanium and all of the winners were selected by Aviation Week Network editors who reviewed dozens of nominations, embody the spirit of exploration, innovation and vision that will inspire others to strive for broad-reaching progress in aviation, aerospace and defence. We look forward to honouring them all, and announcing the Grand Laureates on March 1.”