BMW displays range of metal Additive Manufacturing during Digital Day

April 25, 2018

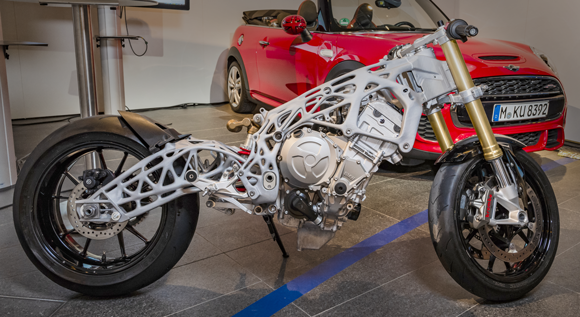

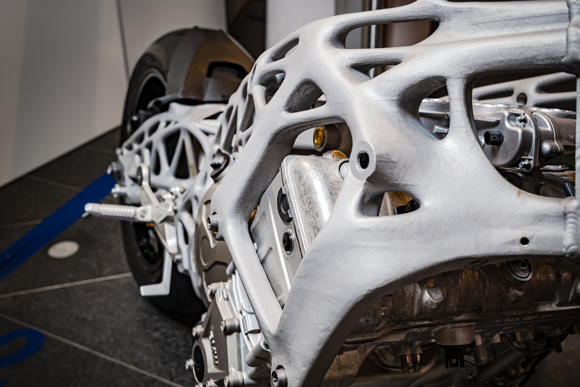

A metal additively manufactured prototype motorcycle frame on display at BMW’s Digital Day

The BMW Group provided an insight into current product developments, technological concepts, innovations and manufacturing processes at its recent Digital Day 2018 event. On show where a range of technologies that also included a number of components from the company’s metal Additive Manufacturing activities.

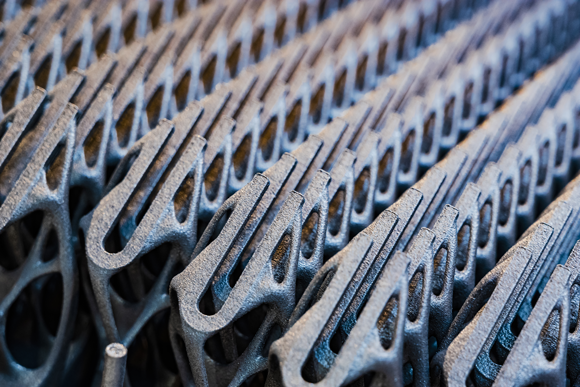

BMW has been utilising Additive Manufacturing in production applications since it began using the process to make water pump wheels for its DTM racing cars in 2010. On display was the latest AM series component found in its new BMW i8 Roadster, an aluminium bracket made using metal powder laser melting for use in the soft-top cover mechanism. The mounting’s standout characteristics are said to include its optimised geometry, lower weight and higher rigidity.

BMW’s new i8 Roadster features a lightweight metal additively manufactured cover carrier bracket

“Additive manufacturing is an integral element of the BMW Group’s production system. The BMW Group considers it one of the key manufacturing methods of the future and a highly promising one. A great deal of its potential lies in series production,” the company stated.

Also on display was a prototype motorcycle frame, made by metal Additive Manufacturing. Although no plans were announced to put the frame into production, BMW expressed the importance of metal AM in the development of new components.

“The Additive Manufacturing Centre housed in the BMW Group’s Research and Innovation Centre in Munich already supplies around 140,000 prototype parts a year to the company’s various development departments,” the company reported. “These range from design samples to plastic mounts and chassis components made from metal. The primary benefit for the developers is that the requested parts are usually available within the space of a few days once the relevant design data has been provided.”