Betatype produces unique titanium additively manufactured watch strap

October 18, 2018

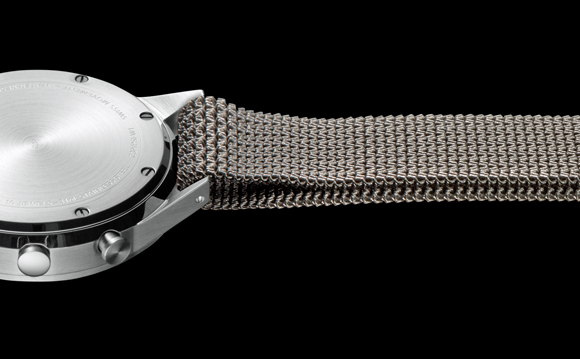

The woven titanium alloy watch strap was produced for Uniform Wares’ PreciDrive M-Line watch collection (Courtesy Uniform Wares)

Betatype Ltd, London, UK, recently teamed up with luxury watchmaker Uniform Wares to design and develop a woven T5 titanium alloy watch strap using metal Additive Manufacturing. The strap is part of Uniform Wares’ PreciDrive M-Line watch collection and reportedly includes a unique clasp that is as strong as a metal bracelet, but light enough to feel like fabric on the wearer’s wrist.

The strap, built on a Renishaw AM250, is comprised of more than 4,000 links that interlock with each other to form a strong, lightweight structure. Unlike in traditional mesh straps, each link is also asymmetrical, meaning that each side of the strap has a differing bend radius. This allows it to be fitted easily over the hand, while remaining flexible enough to be secure on the wrist.

Uniform Wares had previously created a mesh bracelet for their watches using conventional manufactured methods, wherein a large machine weaved steel cable into the mesh pattern, which was then cut to size and working parts welded onto it.

Aerial view of the build plate showing the titanium straps, built on a Renishaw AM250 (Courtesy Uniform Wares)

The strap also features a new type of directional clasp design featuring microscopic ‘teeth’ that have been integrated into the inside of the clasp, which interlocks with the weave of the strap itself. According to the company, this design element could only have been achieved using this unique AM production approach, rather than more traditional methods of welding separate pieces together.

“Every element of the bracelet has been engineered exactly as it needs to work,” stated Michael Carr, Creative Director at Uniform Wares. “The radius at which it curves, the flexibility and stiffness at each point – every link incorporates fine adjustments. It represents bespoke engineering at every point.”

The finished T5 strap, weighing just 10.5 g (Courtesy Uniform Wares)

Betatype’s optimised LPBF process is also said to have used the least amount of material possible, producing little to no waste in the manufacturing of the T5 titanium strap. After manual finishing, the final strap was said to be extremely strong and much lighter than a traditionally-made Milanese mesh bracelet, and weighs just 10.5 g (0.37 oz).

The strap will be available in a natural matt finish with selected references from Uniform Wares’ PreciDrive collection and will be sold via the Uniform Wares website and select retailers, including Porter and Nordstrom. Uniform Wares reported that it is currently in discussion with Betatype about future projects, with Carr stating, “We plan to incorporate what we’ve learned into other aspects of our product. Whatever we decide to do next, we’ll start with the design based on the knowledge of the additive process.”