Authentise releases app for Additive Manufacturing operators

March 18, 2019

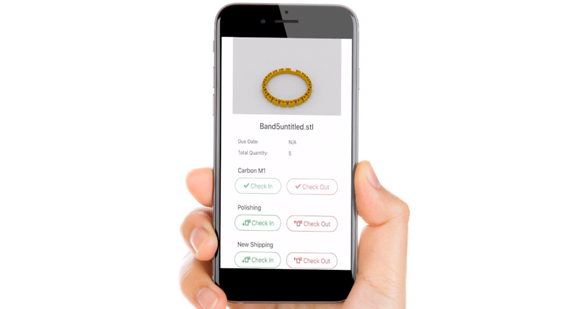

Authentise’s app enables operators to digitally track the manual post-processing of AM parts (Courtesy Authentise)

Authentise, Philadelphia, Pennsylvania, USA, a developer of data-driven workflow tools for Additive Manufacturing, has released a mobile web application for its users. With this tool, Authentise stated that the digital thread is extended from the AM machines, the data of which it has already integrated, through every post processing step.

The app uses scans of QR codes implanted on travellers to help operators move parts through manual post-processing stages, such as powder or support removal, inspection, testing and more. This makes it easier for operators to track parts in progress, which in turn allows managers to see order progress and increases the level of detail available on traceability reports for customers. The data these actions generate can also be used in Authentise’s Machine Learning algorithms to improve time estimates, quality predictions and more.

“Despite the fact that additive devices are nearly entirely digital, the entire process is far from it,” explained Andre Wegner, CEO of Authentise. “Our software already retrieves data from more additive devices than anybody else, as well as some post-processing tools, but that’s not enough. Manual process steps are tedious enough for operators; reporting their progress shouldn’t be. By releasing this app, we’re simply doing what we always do; focus on making the life of the operator easier. The fact that we’re using the data generated to add further value is just added bonus.”

The app is now available as a trial release in the Google Play store or via the web. In addition, Authentise stated that it has released a minimalist traveller that allows AM facilities to begin the process of going completely paperless. Additional functionality will be released in the coming weeks, including the ability to add attachments such as images and notes to each production step, and the ability for operators with the right permissions to jump and undo process steps.