Australian team successfully test-fires metal additively manufactured rocket engine

September 15, 2017

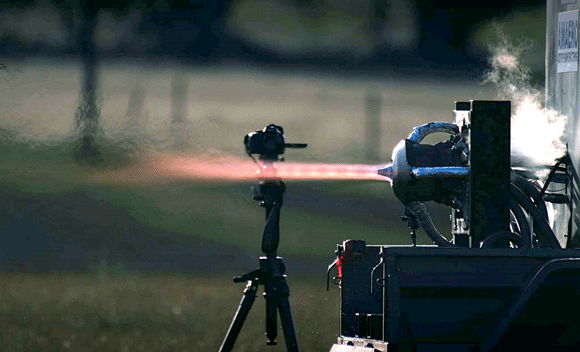

ProjectX engine during a test fire. The shock-cell structure in the rocket plume is visible (Courtesy NextAero)

A team of designers from Australia’s Amaero Engineering and Monash University have designed, manufactured and successfully test-fired a metal additively manufactured rocket engine. The ProjectX engine is built from high-strength nickel based superalloy Hasteloy X on an EOS M280 system and has a design thrust of 4kN (1000 lb).

Having successfully manufactured the world’s first AM jet engine, Amaero reportedly challenged PhD Engineering students at Monash to design an engine which made full use of the geometric complexity enabled by Additive Manufacturing. Graham Bell, Project Lead, stated, “We were able to focus on the features that boost the engine’s performance, including the nozzle geometry and the embedded cooling network. These are normally balanced against the need to consider how on earth someone is going to manufacture such a complex piece of equipment. Not so with Additive Manufacturing.”

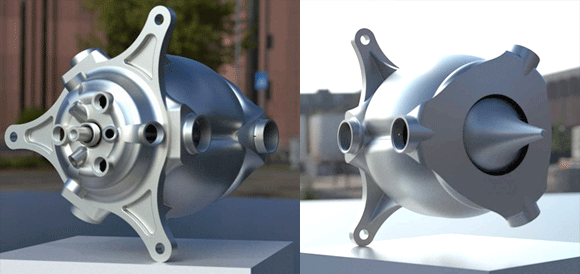

The ProjectX engine is built from high-strength nickel based superalloy Hasteloy X on an EOS M280 system (Courtesy NextAero)

The resulting rocket engine is a complex multi-chamber aerospike design. According to Martin Jurg, an engineer with Amaero, this geometry offers some unique advantages compared to more conventional designs. “Traditional bell-shaped rockets, as seen on the Space Shuttle, work at peak efficiency at ground level. As they climb the flame spreads out reducing thrust. The aerospike design maintains its efficiency but is very hard to build using traditional technology. Using Additive Manufacturing we can create complex designs, print them, test them, tweak them, and reprint them in days instead of months.”

The PhD students involved in the project have now created a company, NextAero, to take their concept to the global aerospace industry, starting with the International Astronautical Congress in Adelaide, September 25-29, 2017. The development of the aerospike rocket was supported by Monash University, Amaero Engineering, and Woodside Energy through the Woodside Innovation Centre at Monash.