Aurora Labs launches its RMP1 Beta Printer for metal AM

May 2, 2019

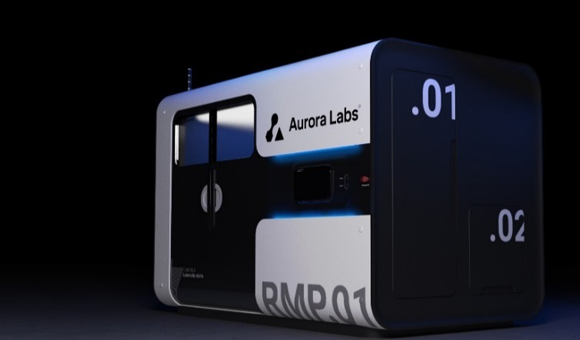

Aurora Labs’ pre-production Additive Manufacturing system – the RMP1 Beta Printer (Courtesy Aurora Labs)

Aurora Labs, Bibra Lake, Australia, has announced that it has finalised the build and first live test of its pre-production Additive Manufacturing system – the RMP1 Beta Printer. The pre-production system is reportedly more sophisticated than Aurora Labs’ previous AM systems. The build plate is 450 mm x 400 mm and can additively manufacture parts ten times the volume of the company’s previous test system (the Alpha2) as well as three times the processing capacity.

According to Aurora Labs, parameters for the initial AM materials have already been developed on the Alpha systems and will only require minimal testing for the RMP1 Beta Printer to allow rapid commercialisation. Along with the upgraded design, these tests are expected to prove the speed increase of the RMP1 Beta system over the Alpha 2. After commissioning the new system, the company will be holding an open day to invite industry partners, investors and individuals from the AM industry to view the technology in action.

David Budge, Aurora Labs’ Managing Director, stated, “The fact that the RMP1 Beta Printer is operational is a key milestone for the team here. Developing and refining our technology has been long in the making and the RMP1 Beta Printer is now built and ready to go live. We are transitioning from a heavy R&D phase with the RMP1 Beta Printer and we will now be able to move to a commercialisation and sales stage much more strongly with the technology we have developed.”

“We have prioritised optimising speed increases and print quality which are key pillars of the Aurora strategy, and the team has made substantial progress achieving speed increases throughout the last few months, resulting in the print of a series of 10mm high, titanium hexagon parts in a time-frame of only 20 minutes. This was particularly notable as numerous industry parties commented on the speed of the machine and the fact that machines they are currently using would take two-three days to achieve a similar result,” continued Budge.

“We are also encouraged by the expressions of interest received from multiple parties for the RMP1 Beta Printer and look forward to updating the market with Aurora’s developments ahead.” The production version of RMP1 is expected to become commercially available within CY2019.