Aurora Labs collaborates with marine propulsion & stabilisation systems maker on large format AM

July 13, 2018

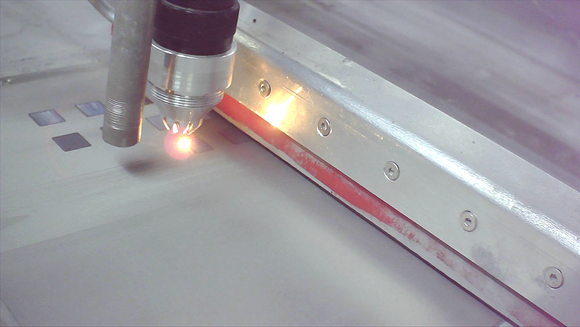

Inside Aurora Labs’ S-Titanium Pro Laser Additive Manufacturing system (Courtesy Aurora Labs Ltd)

Aurora Labs Ltd, Bibra Lake, Western Australia, has signed a deal with marine propulsion and stabilisation systems manufacturer VEEM Ltd, Canning Vale, Western Australia, to investigate the potential of its large format metal Additive Manufacturing technology for VEEM’s gyrostabilisers, as well as its propellers and fin systems. The non-binding agreement is expected to last five years and will see the companies collaborate with the aim of delivering cost and efficiency savings to VEEM’s production.

Aurora manufactures the S-Titanium Pro metal AM system, a medium format machine, and has produced a prototype large format Additive Manufacturing system. It stated that the deal opens the door to the company for further commercial sales opportunities and gives it access to VEEM’s technology and its research and development programme.

According to the partners, the deal’s term sheet is based on a four-stage process. Firstly, VEEM will review and critically analyse Aurora’s technology, products and their potential capabilities. At stage two, Aurora will assist VEEM to assess the potential value of utilising Aurora’s technology and products in VEEM’s operations. At stage three, the companies have agreed to identify and evaluate potential opportunities to secure government R&D funding for related projects, and at stage four, VEEM will be offered the opportunity to make an equity investment in Aurora.

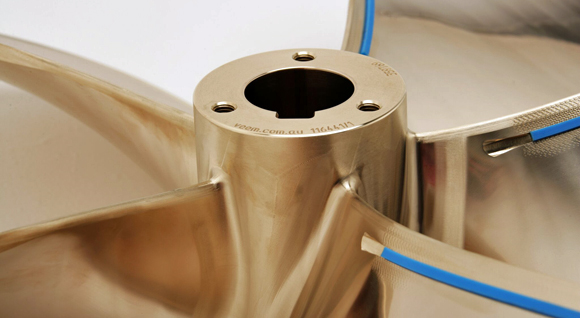

A propeller produced by VEEM’s propeller division (Courtesy VEEM Ltd)

Partnering with VEEM is a significant opportunity for Aurora, the company stated, as the engineering firm would be looking to implement the company’s medium and large format printers when fully developed, therefore making VEEM one of Aurora’s first potential customers for its large format technology. David Budge, Managing Director of Aurora Labs, stated, “We’re extremely pleased to be in talks with VEEM, and their drive to be at the forefront of technology and innovation makes them an ideal industry partner for us.”

“When you couple that to their ambition to dominate the global market in their chosen field, then the unique fit is even more appropriate,” he continued. “VEEM currently creates castings up to fourteen tons in size on a daily basis, and we are looking to help them improve their production capacity through innovative use of our large format technology.”

According to both companies, Aurora’s large format printer could provide significant cost and productivity improvements for VEEM. “With our modern world recognising the finite nature of natural resources and the full cost of energy, the desire to move away from traditional reductive manufacturing is growing,” stated Mark Miocevich, VEEM Managing Director. “Reliability and endurance are critical for high-intensity applications. Aurora Labs has developed the most advanced process we have evaluated and represents a significant step forward in large and rapid 3D printing.”

“VEEM is excited to be able to partner with Aurora Labs to bring the future of Additive Manufacturing into the present, VEEM sees itself as a role model company for the Australian Government’s drive to develop high-end manufacturing exports,” he concluded.