Audi and EOS partnership focuses on holistic approach for metal Additive Manufacturing

January 25, 2017

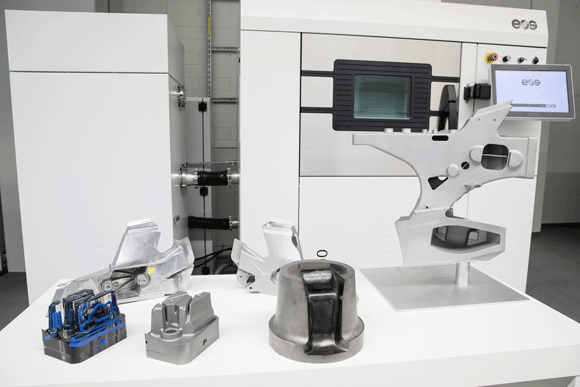

Audi displayed a number of tooling examples at its Smart Factory TechDay

It has been reported that German automaker Audi AG, based in Ingolstadt, Germany, has formed a development partnership with Additive Manufacturing systems provider EOS. The EOS consulting division “Additive Minds” is said to be supporting Audi in the holistic implementation of industrial Additive Manufacturing technology and the development of a corresponding 3D printing centre in Ingolstadt.

“The aim is to not only supply Audi with the right additive systems and processes but to also support them during applications development, when building up internal AM knowledge and training their engineers to become in-house AM experts,” stated Güngör Kara, Director of Global Application and Consulting.

Dr Stefan Bindl, Team Manager Innovation Center, Additive Minds, added, “Audi was looking for a reliable development partner and has found that in EOS. We are very happy about that. The close cooperation concerning application and process development as well as internal knowledge building makes a significant contribution, which is why Audi can quickly achieve substantial effects for their own business by applying our technology.”

Toolmaking and casting technical centre to drive development forward

It was stated that for some time Audi has recognised the potential of Additive Manufacturing for the automotive industry and now promotes the application of the technology, working closely with EOS. On the part of Audi, the sectors of tool making and the casting technical centre for planning have a leading position. Industrial 3D printing is first being applied to equipment and prototype building at Audi, as well as motor sports, where the technology is already in use today.

The use of Additive Manufacturing can revolutionise the process of tool manufacturing. When the component geometry or assemblies are very complicated, the technology will make possible the production of geometries that would have to be joined in conventional manufacturing. Here, AM has an advantage as the design determines the production, not the other way round.

“We have set up our own competence centre for 3D printing in order to gain experience with the materials and the process, and to further develop them for series production. A close cooperation with AM solution providers such as EOS, who can support innovation in technology development, is essential for these aims,” stated Jörg Spindler, Head of Toolmaking, Audi.

“With this technology we are able to integrate internal structures and functions in tools that we have not been able to create so far with conventional manufacturing methods. Especially with components in small batches, we can now produce components using lightweight construction, quickly and economically based on this technology”

Manufacturing parts and vehicle components additively and more cost-effectively

With the application of Additive Manufacturing, Audi is also focusing on the production of inserts for die casting moulds and hot working segments. The company can positively influence the process of series production by conformal cooling, producing parts and vehicle components more cost-effectively. This is made possible by using highly complex, additively manufactured cooling channels, which are tailored to the component and could not be implemented conventionally before. Specifically, the optimised cooling performance leads to a reduction of the cycle time by 20% which has a positive effect on the energy consumption and cost efficiency of the components at the same time.

https://audi-illustrated.com