ASTM’s Additive Manufacturing Center of Excellence launches consortium for materials data and standardisation

May 19, 2022

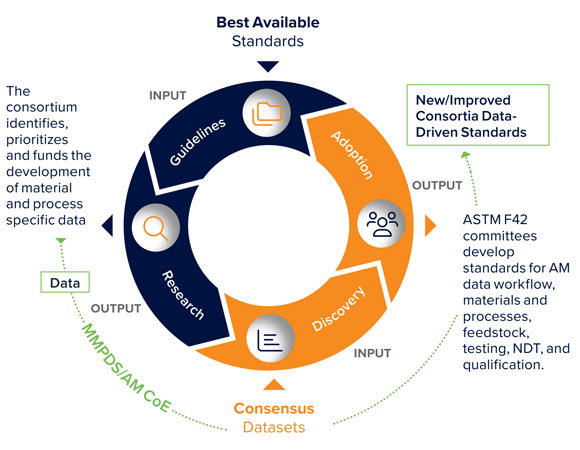

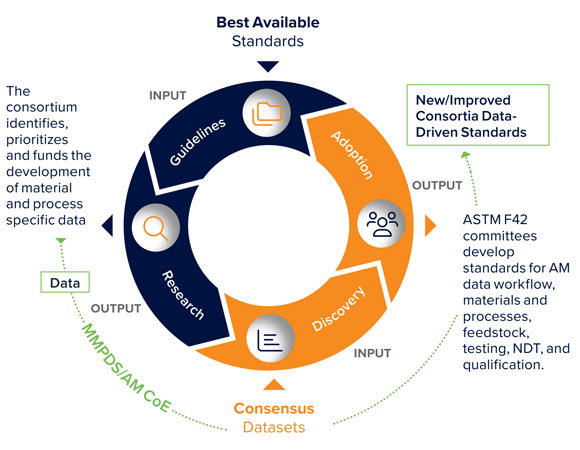

ASTM International’s Additive Manufacturing Center of Excellence (AM CoE) has announced the launch of its Consortium for Materials Data and Standardisation (CMDS) initiative, with the aim of bringing key organisations together, from across a broad range of industries representing the entire AM value stream, to collaborate on standardisation of the requirements for AM materials data generation.

The consortium is being launched with 21 founding members, and will create and manage shared high pedigree reference datasets needed to accelerate qualification and greater adoption of AM technologies.

The CMDS approach is particularly focused on determining key process-structure-property relationships necessary to develop methods for generating machine agnostic materials data. The CMDS will curate a shared database of high-pedigree data that will be used by consortium members to develop the tools, such as physics-based/probabilistic models, and data analytics needed to support rapid qualification of new AM applications, materials and technologies and real-time quality assurance to scale AM production.

The founding members include:

- Accurate Brazing

- AddUp Inc.

- ASTM International

- Auburn University

- BeamIT/3T-AM Ltd.

- Boeing

- Desktop Metal

- Element Materials Technology

- EOS

- Edison Welding Institute (EWI)

- Fraunhofer IAPT

- Gasbarre Thermal Processing Systems

- GE Additive

- GKN Additive

- Hexagon Manufacturing Intelligence, Inc.

- HP Inc.

- Manufacturing Technology Center (MTC)

- Morf3D

- National Aeronautics and Space Administration (NASA)

- Raytheon Technologies Corporation

- Sigma Labs, Inc.

Each year, under the direction of the industry members and in coordination with key regulatory bodies and other government agencies, the CMDS will select materials and application specific properties (e.g., static, cyclic, thermal, corrosion) of interest and execute various projects that ultimately support the development of standards and datasets.

While members retain exclusive use of the full datasets to support their business, research output and lessons learned will inform new AM standards and specifications developed through the ASTM related committees such as F42 to drive consistency across the industry, creating new and improved materials specifications with property and structure requirements based on robust datasets.

“This initiative connects industry, academia, and government teams to accelerate the path for additive adoption, moving Additive Manufacturing from a process with significant financial barriers to a standard manufacturing process for widespread use,” stated Jeff Shubrooks, Raytheon Missiles and Defense Additive Manufacturing Technology Area Lead. “Raytheon Technologies is bringing their experience and diverse research and data to help create the standards and necessary qualification methods.”

Nicholas Mule, Director, Boeing Additive Manufacturing Intelligence Center, added, “The Boeing team is excited to join the AM CoE Industry Consortium and collaborate with the AM CoE industry members to mature and accelerate the industrial adoption of additive manufacturing. The collective AM expertise of the members provide the broad perspective needed to advance the AM industry and drive towards the common AM standards needed for sustained adoption.”

The AM CoE partners supporting the core technical activities and execution of the CMDS are ASTM International, NASA and Auburn University. This membership-driven consortium is intended to strengthen AM CoE’s core mission of research to standards (R2S) filling standardisation gaps while enabling access to high quality datasets.

“GE Additive is pleased to continue its engagement with the AM CoE Industry Consortium. As a company that offers the entire additive ecosystem, from feedstock to finished parts, we recognise the importance of developing highly pedigreed materials property datasets. By coming together to define a common approach to materials characterisation, we hope to drive further understanding and expansion of the additive industry as a whole,” added Amber Andreaco, Section Manager – Materials & Powders, GE Additive.